Abstract

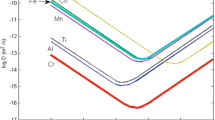

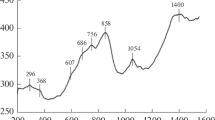

The oxidation behavior of Fe-5M-C alloys (where M is Si, Ti, V, Nb, Ta, Cr, W, or Ni, and C is 0, 0.1, 0.4, 0.8 or 1.2 wt.%) has been studied in the temperature range of 600–850°C in one atmospheric pressure of oxygen. Except for Si-containing alloys, all the alloys exhibited a parabolic rate law during oxidation, and the oxidation rate increased with increasing carbon content. The deviations from the above generalization can be explained on the basis of either phase composition of the alloy matrix at the oxidation temperature or carbon losses incurred during oxidation. Alloys rich in carbide phases have much lower oxidation rates than alloys containing solid-solution phases. This has been attributed to the decrease in mobility of carbon in iron-base alloys in the presence of a carbide-formin addition. The disruption of the oxide scales, which is the result of decarburization, also influences the oxidation behavior of iron-base alloys. At the 1.2% C level, the parabolic rate constant, Kp, follows the order:

The order is approximately similar to the increasing free energy sequence for the oxidation of carbides to oxides in Fe-5M-C alloys.

Similar content being viewed by others

References

A. U. Malik and D. P. Whittle,Oxid. Met. 16, 339 (1981).

A. U. Malik, The influence of carbon on the oxidation of iron-base alloys, Ph.D. thesis, University of Liverpool (1975).

ASM Metal Hand Book, Vol. VIII (1973).

ASMMetal Hand Book (1948), p. 1256.

C. A. Dirsch,Rep. Br. Elect. Ind. Res. Assoc., JIEFT 125, (1940).

H. Flender and H. Wever,Arch Eisenhuttenwes. 34, 727 (1963).

Y. V. Grdina et al., Iza Vysshikhuchebn Zavedenu,Chernya Met. 4, 124 (1966).

H. J. Goldschmidt,Interstitial Alloys (Butterworths, London, 1967).

H. Eggers and W. Peter,Mittk-Wilhelm—Inst. Eisenforsch, Dusseld 20, 205 (1938).

K. Kuo,J. Iron Steel Inst. 173, 368 (1953).

C. B. Pallack and H. H. Stadelmier,Met. Trans. 1, 535 (1970).

H. Krainer,Arch. Eisenhuttenwes. 21, 33 (1950).

H. Harvig and B. Uhrenius, TRITA-MAC-0008,Royal Institute of Technology, Stockholm (1971).

H. Harvig and B. Uhrenius,Metal Sci. 9, 67 (1973).

J. S. Marsh,The Alloys of Iron and Nickel, Vol. I, Engineering Foundation (McGraw-Hill, New York, 1938).

P. L. G. Samuel, L. G. Finch, and J. R. Rait,Nature 175, 37 (1955).

M. A. Krishtal and Yu. I. Davydov, Influence of Cr and W on the diffusion and thermodynamic activity of C in Fe alloys,Chernaya Met. 9, 133 (1965).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Malik, A.U. High-temperature oxidation of transition metal, carbide-dispersed iron-base alloys. Oxid Met 24, 233–263 (1985). https://doi.org/10.1007/BF00657060

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00657060