Conclusions

-

1.

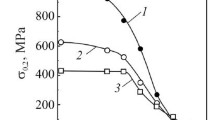

Bushings of graphitized steel have the best wear resistance when the microstructure consists of divorced pearlite and compact graphite inclusions.

-

2.

From the microstructural changes in the working surface it was possible to determine the wearing qualities of bushings with the same hardness but a different structure of the matrix—lamellar pearlite and ferrite or spheroidized pearlite.

Similar content being viewed by others

Literature cited

S. A. Saltykov, Stereometric Metallography [in Russian], Metallurgiya, Moscow (1970).

A. A. Baranov et al., Grain Growth in Steel during Thermal Cycling [in Russian], Tekhnika, Kiev (1967), p. 138.

K. P. Bunin, A. A. Baranov, and É. N. Pogrebnoi Graphitization of Steel [in Russian], Izd. AN UkrSSR, Kiev (1961).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 67–69, September, 1973.

Rights and permissions

About this article

Cite this article

Pritomanova, M.I., Shchedrina, F.I. Structure and operating characteristics of graphitized steel. Met Sci Heat Treat 15, 803–805 (1973). https://doi.org/10.1007/BF00656299

Issue Date:

DOI: https://doi.org/10.1007/BF00656299