Conclusions

-

1.

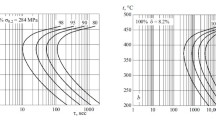

Raising the heating temperature and the cooling rate leads to an increase in the structural instability of alloy VT16 and has a considerable effect on the mechanical properties and phase composition.

-

2.

The lowest value of the yield strength after quenching from different temperatures corresponds to the largest amount of β phase. At first the yield strength decreases sharply with increasing quenching temperatures, coinciding with the formation of α″ phase.

-

3.

The increase in strength of samples quenched and annealed with heating to 750–900°C is identical. For annealed samples it is somewhat lower at small degrees of deformation, and for quenched samples at large degrees of deformation. In this case the ductility (ψ and δ5) of the quenched samples is somewhat higher than for the annealed samples.

Similar content being viewed by others

Literature cited

K. K. Vul'f, Heat Treatment of Titanium Alloys [in Russian], Metallurgiya, Moscow (1969).

V. A. Livanov, B. A. Kolachev, and N. S. Lyasotskaya "Heat treatment of titanium and its alloys," in: Titanium Alloys for New Technology [in Russian], Nauka, Moscow (1968).

G. I. Nosova, Phase Transformations in Titanium Alloys [in Russian], Metallurgiya, Moscow (1968).

V. N. Moiseev and L. V. Geras'kova, "Change in the structure and properties of titanium alloys in relation to heat treatment," Metal. i Term. Obrabotka Metal. No. 5, 3–5 (1965).

M. I. Ermolova, É. V. Polyak, and O. P. Solomina, "Phase and structural changes in two-phase commercial alloys," in: Titanium Alloys for New Technology [in Russian], Nauka, Moscow (1968).

A. I. Khorev and L. V. Geras'kova, "Heat treatment of alloys VT14, VT15, and VT16," Metal. i Term. Obrabotka Metal., No. 5, 48–50 (1965).

E. A. Vinogradova, N. F. Lashko, and V. N. Moiseev, "Metastable structural transformations and their effect on the properties of α+β titanium alloys," in: Titanium and Its Alloys [in Russian] (1963), pp. 293–299.

R. Wood, Acta Met.,11, No. 8, 907 (1963).

S. Ueinig et al., J. Metals,6, No. 11, Section 2 (1954).

R. Hiltz, Trans. Met. Soc. AIME,215, 138 (1959).

D. Williams et al., Trans. Met. Soc. AIME,230, 256 (1964).

V. A. Skudnov, "Determining true strain in the neck of tensile test samples," Zavod. Lab., 31, No.7, 871–873 (1965).

Additional information

A. A. Zhdanov Gor'kii Polytechnical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 49–52, September, 1973.

Rights and permissions

About this article

Cite this article

Mal'tsev, M.V., Volkova, T.N. & Skudnov, V.A. Effect of cooling rate on the phase composition and mechanical properties of alloy VT16. Met Sci Heat Treat 15, 781–784 (1973). https://doi.org/10.1007/BF00656293

Issue Date:

DOI: https://doi.org/10.1007/BF00656293