Conclusions

-

1.

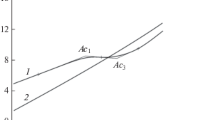

Silicon (0.3–1.5%) and nickel (0.10–3.3%) have a negligible effect on the hardenability of die steels of the 4Kh4VMFS type. The susceptibility of such steels to overheating increases notably with the nickel concentration but hardly varies with increasing silicon concentrations.

-

2.

Alloying die steels of the 4Kh4VMFS type with nickel* is inexpedient, since it does not improve the plasticity or impact toughness at 20°C and leads to a sharp reduction of heat resistance and strength at elevated temperatures.

Similar content being viewed by others

Literature cited

L. A. Poznyak and S. I. Tishaev, Metal. i Term. Obrabotka Metal., No. 1 (1969).

M. A. Krishtal, Diffusion Processes in Iron Alloys [in Russian], Metallurgizdat, Moscow (1963).

A. P. Gulyaev, Metal. i Term. Obrabotka Metal. No. 8 (1965).

Ya. I. Spektor et al., Dokl. Akad. Nauk SSSR,155, No. 5 (1964).

S. Florren, Trans. AIME,230, No. 4 (1964).

Additional information

UkrNIISP ETsSTAL'. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 61–64, June, 1969.

Rights and permissions

About this article

Cite this article

Tishaev, S.I., Poznyak, L.A. Properties of die steels with silicon and nickel. Met Sci Heat Treat 11, 491–494 (1969). https://doi.org/10.1007/BF00656253

Issue Date:

DOI: https://doi.org/10.1007/BF00656253