Conclusions

-

1.

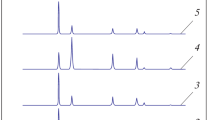

On the basis of the diagram of the isothermal transformation of the β2-solution in the YuNDK35T5 alloy we have shown the possibility of quenching this alloy from two temperature ranges: 1260–1240 and 900–850°C.

The cooling rate at the higher temperatures must be no lower than 100°/min. A lower cooling rate induces high temperature decomposition, and as the result there is a sharp decrease of the magnetic qualities.

-

2.

Cooling at 820–600°C must be carried out at the rate of 20–30°/min.

-

3.

We recommend isothermal treatment at the temperature at which the decomposition is most intense (700°C).

-

4.

External magnetic field is effective at the temperature at which the decomposition begins (formation of nuclei). When the cooling rate is about 20°/min the magnetic field is effective at 800–760°C.

-

5.

One must use multistage tempering for the YuNDK35T5 alloy.

Similar content being viewed by others

Literature cited

B. G. Livshits and V. S. L'vov, Alloys with High Coercive Force [in Russian], Metallurgizdat, Moscow (1960)

A. A. Shekalov, Trudy NII TV4, No 1–2 (1960).

A. S. Zaimovskii and L. M. L'vova, Stal', No. 4 (1945).

Ya. M. Dovgalevskii, ZhTF,22, No. 1 (1952).

G. F. Golovin and A. A. Shekalov, ZhTF,24, No. 6 (1954).

E. Wahlfarth. Adv. Phys.,8 (1959).

W. Zumbusch, Zeitschrift für Metallkunde49, No. 1 (1958).

E. G. Povolotskii, Ya. M. Dovgalevskii, and V. K. Baitina, Izvestiya vysshikh uchebnykh zavedenii, Chernaya Metallurgiya, No. 1 (1963).

E. G. Povolotskii, Ya. M. Dovgalevskii, and V. K. Baitina, MiTOM, No. 11 (1963).

Author information

Authors and Affiliations

Additional information

Translated from metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 11–16, February, 1965

Rights and permissions

About this article

Cite this article

Baitina, V.K., Vlaskina, K.I. & Dovgalevskii, Y.M. Heat treatment of the YuNDK35T5 alloy. Met Sci Heat Treat 7, 81–86 (1965). https://doi.org/10.1007/BF00655808

Issue Date:

DOI: https://doi.org/10.1007/BF00655808