Conclusions

-

1.

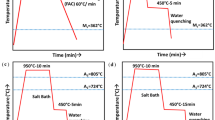

The development of brittleness in 20GMR steel at cooling rates of 20–30°/min is due to the greatly deformed structure of low-carbon martensite, in which dislocations are strongly pinned by carbon atoms.

-

2.

The following mechanical properties can be obtained in parts of 20GMR steel 5–70 mm thick as the result of deformation at 800–700°C during uninterrupted cooling: σb = 145-120 kg/mm2, σ0.2 = 100-80 kg/mm2; δ=10–15%.

-

3.

TMT of bainitic steels can be conducted during cooling in air without any additional heat treatment.

Similar content being viewed by others

Literature cited

M. Economopoulos, T. Greday, and L. Habraken, Rev. Met. (1965).

K. Irvine and F. Pickering, J. Iron Steel Inst. (1965).

K. Potaszkin and K. Bar-Avi, Rev. Met.,55 (1957).

M. Economopoulos and L. Habraken, CNRM (1966).

P. Kelly and J. Nutting, J. Iron Steel Inst. (1959, 1961).

D. Shackleton and P. Kelly, Joint BISRA-ISI Conf., Martensite and Bainite (1965).

W. Koster, L. Bangert, and K. Hahn, Arch. Eisenhüttenw.,25 (1957).

B. Ya. Drozdov, L. I. Kogan, and R. I. Éntin, Fiz. Met. i Metallov.,13 (1962).

Additional information

Institute of Metallurgy of the Academyof Sciences of the GruzSSR. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 22–26, May, 1967.

Rights and permissions

About this article

Cite this article

Zoidze, N.A., Habraken, L., Economopulos, M. et al. Thermomechanical treatment of 20GMR steel during uninterrupted cooling. Met Sci Heat Treat 9, 351–354 (1967). https://doi.org/10.1007/BF00655025

Issue Date:

DOI: https://doi.org/10.1007/BF00655025