Conclusions

-

1.

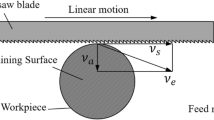

Band saws of steel V2F can be heat treated by means of flame hardening and combined heating (high-frequency induction and gas burner).

-

2.

Under optimal conditions the heat treatment ensures hardening of the teeth to HRC 62-65 to a distance of 0.5–0.8 mm from the tip of the teeth, the hardness of the valleys not exceeding HRC 45.

-

3.

The productivity of hardening with combined heating is five to six times that of standard flame hardening.

-

4.

The durability of band saws in cutting ferrous metals is 6–12 h (or 0.6–2.0 m2 of sawed material), which is three to five times the durability of saws made of steel U10A.

Similar content being viewed by others

Literature cited

L. A. Poznyak, G. M. Ryzhkov, et al., Metal. i Term. Obrabotka Metal., No. 12 (1967).

Tekhnologiya Mashinostroeniya, No. 3 (1965), Ref. 3B333P.

V. V. Bykov, Apparatus for Gas Welding and Cutting [in Russian], Bibliotechka Avtogenshchika, No. 11-12, Mashgiz (1964).

Yu. A. Geller, Tool Steels [in Russian], Metallurgizdat, Moscow (1968).

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 71-74, October, 1970.

Rights and permissions

About this article

Cite this article

Kleptsov, L.G., Surnin, F.E. & Vovk, V.N. Heat treatment of band saws of steel V2F. Met Sci Heat Treat 12, 882–884 (1970). https://doi.org/10.1007/BF00654483

Issue Date:

DOI: https://doi.org/10.1007/BF00654483