Conclusions

-

1.

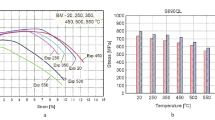

High-temperature thermomechanical treatment of spring steels 60S2 and 60S2F in strips 15 m long rolled by the usual procedure increases the ultimate tensile strength by comparison with the properties resulting from quenching (tempering 1 h at 400°C in both cases). Sharp cooling during TMT does not lead to excessive warping.

-

2.

The developed intermediate tempering treatment retains the strength of steel 60S2F resulting from HTTMT during further heat treatment even when the steel is heated in the furnace for repeated quenching.

-

3.

After TMT, double intermediate tempering followed by the usual heat treatment produces the following properties of steel 60S2F: σb=220 kg/mm2, σ0.2=200 kg/mm2, ψ=43%, δ=6%.

Similar content being viewed by others

Literature cited

M. L. Bernshtein and A. G. Rakhshtadt, Stal', No. 1 (1962).

M. L. Bernshtein and V. D. Kal'ner, in: Thermomechanical and Thermomagnetic Treatments [in Russian], GOSINTI (1963).

V. V. Andreeva, M. L. Bernshtein, et al., Stal', No. 3 (1967).

D. A. Prokoshkin, A. G. Rakhshtadt, and A. V. Supov, Stal', No. 3 (1967).

Additional information

Moscow Institute of Steel and Alloys, Chusovskoi Metallurgical Plant. Translated from Metallovdenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 56–59, July, 1968.

Rights and permissions

About this article

Cite this article

Bernshtein, M.L., Gustomesov, A.V., Kanev, V.P. et al. Commercial tests of thermomechanical strengthening of spring steel. Met Sci Heat Treat 10, 552–554 (1968). https://doi.org/10.1007/BF00654367

Issue Date:

DOI: https://doi.org/10.1007/BF00654367