Conclusions

-

1.

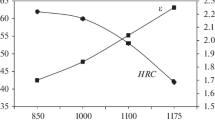

The effective increase of wear resistance ε depends on the degree of plastic deformation during HTTMT (curves 2, 3 in Fig. 1).

For the steel investigated the optimal deformation is 30%.

-

2.

The wear resistance of samples subjected to treatment 3 (curve 3) is higher than that of samples subjected to treatment 2.

Similar content being viewed by others

Literature cited

D. I. Bron and I. I. Levites, Metal. i Term. Obrabotka Metal., No.9 (1966).

D. A. Brokoshkin, A. G. Vasil'eva, et al., Metal i Term. Obrabotka Metal., No. 9 (1966).

M. M. Khrushchov, Zavod, Lab., No. 3 (1962).

M. A. Krishtal and I. Ya. Ryazantsev, Metal. i Term. Obrabotka Metal., No. 9 (1966).

A. P. Gulyaev and A. S. Shigarev, Metal. i Term. Obrabotka Metal., No. 4 (1963).

Additional information

Bryanskii Institute of Transportation Machinebuiding. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 38–39, July, 1968.

Rights and permissions

About this article

Cite this article

Zharkov, V.Y. Effect of repeated quenching after HTTMT on the abrasive wear resistance of chromium structural steel. Met Sci Heat Treat 10, 533–534 (1968). https://doi.org/10.1007/BF00654360

Issue Date:

DOI: https://doi.org/10.1007/BF00654360