Conclusions

-

1.

Carburizing and nitrocementation improve the residual stresses in comparison with uncarburized samples. This leads to higher fatigue strength and longer lifetimes of machine parts.

-

2.

The residual stresses in carburized and nitrocementated parts are of complex nature due to the three stress components (thermal, structural, and the stress resulting from the difference in specific volume through the cross section of the piece).

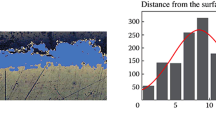

The sum of the first two stress components is positive in the surface layers after through-hardening in oil. The third component is of negative sign. Of the total stress, the highest compressive stress occurs at some distance below the surface.

-

3.

The magnitude of the stress depends on the sample size, the hardenability, the depth of carburizing and nitrocementation, the cooling rate, and other factors. Thus, the magnitude and sign of the stress after carburizing and nitrocementation can vary within wide limits.

-

4.

The residual stresses in carburized and nitrocementated parts are improved considerably by shot hardening, which induces substantial compressive stresses in the surface.

Similar content being viewed by others

Literature cited

L. S. Moroz and S. S. Shurakov, Problems of Strength of Carburized Steel [in Russian], Leningrad (1947).

L. S. Elenevskii, Vestnik Mashinostroeniya, No. 9 (1958).

N. F. Vyaznikov and S. S. Ermakov, Metal. i Term. Obrabotka Metal., No. 6 (1959).

D. A. Sveshnikov, I. V. Kudryavtsev, N. A. Gulyaeva, and L. D. Golubovskaya, Metal. i Term. Obrabotka Metal., No. 7 (1966).

D. A. Sveshnikov, Metal. i Term. Obrabotka Metal., No. 4 (1964).

M. A. Balter and N. M. Grinberg, Metal. i Term. Obrabotka Metal., No. 6 (1962).

D. M. Nakhimov and A. G. Vasil'eva, in: Structure and Properties of Heat-Treated Steels [in Russian], Mashgiz, Moscow (1951).

D. M. Nakhimov and N. M. Grinval'd, ibid in:.

N. N. Davidenkov and E. M. Shevandin, Zh. Tekh. Fiz.,9, No. 12 (1939).

K. S. Kolev. Zavod. Lab., No. 2 (1958).

Additional information

All-Union Correspondence Polytechnical Institute; NIITabtoprom. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 22–26, July, 1968.

Rights and permissions

About this article

Cite this article

Nakhimov, D.M., Novikova, A.Y. Residual stresses after carburizing and nitrocementation. Met Sci Heat Treat 10, 518–520 (1968). https://doi.org/10.1007/BF00654354

Issue Date:

DOI: https://doi.org/10.1007/BF00654354