Conclusions

-

1.

By comparison with quenched and tempered samples, cyanided and nitrided samples of 3Kh2V8 steel have a substantially higher surface hardness at room and elevated temperatures and are less susceptible to cracking under sharp variations of thermal loading.

-

2.

Low-temperature gas cyaniding of 3Kh2V8 steel is better than nitriding, since it is possible to obtain a cyanided case without ε phase, which ensures better mechanical properties.

-

3.

The use of low-temperature gas cyaniding conducted under the optimum conditions (560°C, 5–7 h) doubles the durability of molds for pressure casting and substantially reduces casting rejects due to fins.

Similar content being viewed by others

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 71–72, July, 1967.

Rights and permissions

About this article

Cite this article

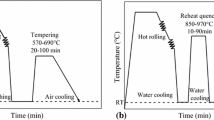

Smirnov, A.M., Lyutenko, A.E. & Oryshich, I.V. Conditions of quenching, tempering, nitriding, and low-temperature gas cyaniding of 3Kh2V8 steel. Met Sci Heat Treat 9, 556–557 (1968). https://doi.org/10.1007/BF00654267

Issue Date:

DOI: https://doi.org/10.1007/BF00654267