Conclusions

-

1.

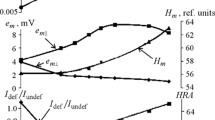

The hardening of 28Kh10G8M4 steel during cold-plastic deformation is due to the formation of martensite resulting from deformation and to cold working of the austenite.

-

2.

Hot rolling at 1100°C, with subsequent cold deformation with 30% deformation and tempering at 500°C for 1 h, results in the following characteristics: σb=190–215 kg/mm2, δ=15–20%, and aH=6–8 kgm/cm2 (tested at 20°C).

Similar content being viewed by others

Literature cited

O. I. Kovalenko, O. A. Bannykh, and M. V. Pridantsev, Izv. AN SSSR, OTN (1965), No. 2.

S. I. Belyaev, Zavodskaya laboratoriya (1946), No. 11–12.

Additional information

A. A. Baikov Metallurgy Institute Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 25–29, February, 1966

Rights and permissions

About this article

Cite this article

Bannykh, O.A., Kovalenko, O.I. & Pridantsev, M.V. Strengthening of Cr−Mn−Mo steel by cold-plastic deformation. Met Sci Heat Treat 8, 117–120 (1966). https://doi.org/10.1007/BF00652601

Issue Date:

DOI: https://doi.org/10.1007/BF00652601