Conclusions

-

1.

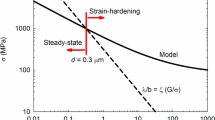

The Bauschinger effect decreases with increasing grain size, probably due to the decrease in the total area of the grain boundaries, on which residual microstresses are created and also due to the possible occurrence of larger deformations within large grains as the result of smaller changes in the surface state of the boundary than in small grains.

-

2.

The behavior of a material under a load of changing sign depends on the type of crystal lattice. Materials with hexagonal lattices have a larger Bauschinger effect than materials with a cubic lattice (either body-centered or face-centered) because of the strong anisotropy of the hexagonal lattice, and also because the mechanism of plastic deformation in these materials depends on the type of stress and the sequence in which the sign of the stress is changed.

Similar content being viewed by others

Literature cited

S. I. Ratner and Yu. S. Danilov, Zavodskaya laboratoriya, No. 4 (1950).

Additional information

Central Scientific Institute of Ferrous Metallurgy Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 38–41, September, 1964

Rights and permissions

About this article

Cite this article

Danilov, Y.S. Effect of grain size on the Bauschinger effect. Met Sci Heat Treat 6, 563–565 (1964). https://doi.org/10.1007/BF00652409

Issue Date:

DOI: https://doi.org/10.1007/BF00652409