Conclusions

-

1.

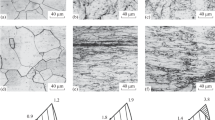

Cold-rolled VT1 titanium sheet has a pronounced anisotropy of the elasticity modulus (up to 12%). The highest elasticity modulus is at an angle of 720 to the rolling direction and the lowest in the rolling direction.

-

2.

Up to the beginning recrystallization temperature the elasticity modulus increases monotonically in all directions.

-

3.

On recrystallization the increase of the elasticity modulus ceases to be monotonic — in one direction the modulus declines sharply and in another continues to increase, although the character of the anisotropy changes little. This indicates that the previous texture is retained after recrystallization.

Similar content being viewed by others

Literature Cited

A. E. Bryukhanov, Zh. Tekh. Fiz.,6, No. 3 (1936).

A. A. Bryukhanov, Z. A. Baranovskaya, and A. E. Bryukhanov, Metal. i Term. Obrabotka Metal., No. 6 (1966).

V. V. Glazova, Alloying of Titanium [in Russian], Metallurgiya, Moscow (1966).

Additional information

Odessa State University. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 67–68, February, 1969.

Rights and permissions

About this article

Cite this article

Zakharchenko, I.G., Bryukhanov, A.E. Variation of young's modulus with annealing of titanium sheet. Met Sci Heat Treat 11, 153–154 (1969). https://doi.org/10.1007/BF00652290

Issue Date:

DOI: https://doi.org/10.1007/BF00652290