Conclusions

-

1.

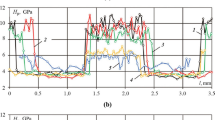

The optimum combination of mechanical properties results from thermomechanical treatment and tempering at 100°C. After ordinary quenching and tempering at 100°C σb=200 kg/mm2, while after high-temperature thermomechanical treatment σb=215 kg/mm2, and after low-temperature thermomechanical treatment σb=238 kg/mm2 (ε=80%). Under the same conditions, the yield strength changes from 160 to 170 and 185 kg/mm2. The strength increases from 232 to 317 and 330 kg/mm2, mainly as the result of the great increase in reduction of the section after thermomechanical treatment (ψ changes from 30 to 52 and 42% respectively). The relative elongation increases from 9 to 11.5% (high-temperature thermomechanical treatment) and 10.8% (low-temperature thermomechanical treatment), and the impact strength increases from 5.3 to 6.5 and 8.1 kgm/cm2 respectively.

-

2.

The highest ductility and impact strength result from deformation at 700–850°C, while the highest strength results from deformation at 550–850°C. The increase in ductility apparently depends on the process of recovery in austenite.

-

3.

An increase in the degree of plastic deformation from 30 to 80% increases the ductility, while the strength remains the same. Apparently this is due to heating of the sample induced by deformation and the processes occurring as the result of recovery.

-

4.

The recrystallization resulting from thermomechanical treatment (deformation 70–80% at 850°C) leads to considerable increase in ductility without decreasing the strength. Thus, recrystallization has a favorable effect on the results of thermomechanical treatment under the conditions tested.

-

5.

It was shown that the relationship between the hardness and the ultimate strength of the steel ceases to exist as the degree of plastic deformation increases. Therefore, hardness is not a characteristic of the degree of strengthening induced by thermomechanical treatment.

Similar content being viewed by others

Literature Cited

V. Zackay and W. Justusson, Spec. Rept. Iron and Steel Institute, No. 76 (1962).

Additional information

All-Union Correspondence Machine Construction Institute; Central Scientific Research Institute of Machine Construction Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 16–21, August, 1964

Rights and permissions

About this article

Cite this article

Blanter, M.E., Prozorov, L.V., Lavrent'eva, L.P. et al. Effect of thermomechanical treatment, including extrusion, on the mechanical properties of steel. Met Sci Heat Treat 6, 484–489 (1964). https://doi.org/10.1007/BF00652144

Issue Date:

DOI: https://doi.org/10.1007/BF00652144