Conclusions

-

1.

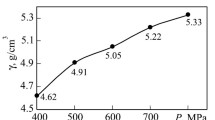

Nitriding of iron-fluoride materials increases the wear resistance 3–3.5 times.

-

2.

The optimal antifriction properties result from nitriding at 500°C for 1 h.

-

3.

It was found that the activation energy of nitriding porous iron with 5% calcium fluoride matches the activation energy of nitriding solid iron.

Similar content being viewed by others

Literature cited

Yu. F. Shevchuk et al., Poroshkovaya Metallurgiya, No. 12 (1968).

J. Fast and M. Verrig, J. Iron Steel Inst., No. 24 (1954).

Yu. M. Lakhtin, Physical Basis of the Nitriding Process [in Russian], Mashgiz, Moscow (1948).

Additional information

Problems of Material Science Institute of the Academy of Sciences, UkrSSR, Kiev Polytechnical Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 8, pp. 21–24, August, 1969.

Rights and permissions

About this article

Cite this article

Shevchuk, Y.F., Miroshnikov, V.N., Moskalenko, Y.N. et al. Antifriction properties of nitrided materials of the iron-fluoride system. Met Sci Heat Treat 11, 610–612 (1969). https://doi.org/10.1007/BF00652114

Issue Date:

DOI: https://doi.org/10.1007/BF00652114