Conclusions

-

1.

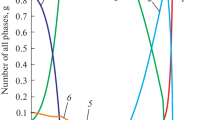

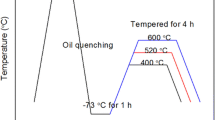

Heating of steel Kh17N2 to 1000–1300°C for 1 to 5 mins followed by air cooling results in a martensitic structure with a 545–649 kg/sq. mm microhardness, which reduces the impact toughness of the metal to 0.36–0.60 kgm/sq.cm.

-

2.

Tempering in the 300–600°C range causes a precipitation of fine Cr carbides from the martensite and depletion in chromium of the martensite substance. The tempered martensite has a low corrosion resistance.

-

3.

After tempering at 400–650°C the character of the corrosion changes to structurally-selective and intercrystalline: the areas of tempered martensite are corroded, those of chromium ferrite are not.

-

4.

Tempering of steel Kh17N2 at 680–700 C/1 hr results in a complete decomposition of martensite into a ferrite-carbide mixture, this resulting in a relief of the residual stresses and a formation of stable chromium carbides at the grain boundaries.

-

5.

Heating of the quenched steel at 750, 800, 850, 900–1300°C/30 mins causes intercrystalline corrosion in tests on specimens in an aqueous solution of copper sulfate and sulphuric acid. Heating above 800°C followed by a relatively rapid cooling produces susceptibility to intercrystalline corrosion.

-

6.

Weldments on this steel performed with austenitic electrodes are prone to structurally-selective and intercrystalline corrosion in the HAZ after multi-layer arc welding or welding with pre-welding. To prevent this, it is necessary to temper the welded parts at 680–700°C/1 hr.

Similar content being viewed by others

References

Kehsin Kuo, Journal Iron Steel Inst., v. 173, 1953, No. 4, 363–375.

N. I. Kakhovskii, Avtom. Svarka, v. 11, 1958, No. 6, 64–69.

Additional information

Research Institute for Chemical Apparatus

Rights and permissions

About this article

Cite this article

Akshentsevo, A.P. Structural changes and corrosion resistance of [17% Cr, 2% Ni] steel Kh17N2. Met Sci Heat Treat 2, 583–587 (1960). https://doi.org/10.1007/BF00651927

Issue Date:

DOI: https://doi.org/10.1007/BF00651927