Conclusions

-

1.

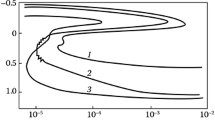

Steel 000Kh16N15M3 has a very low susceptibility to ICC only when the carbon concentration is below 0.02%. The depth of the attack is slight at tcr=650–700°C.

-

2.

Alloying with niobium eliminates susceptibility to ICC at carbon concentrations up to 0.03%.

-

3.

Up to 0.13% N has no effect on susceptibility to ICC in the steel with 0.003% C; at 0.03% C the susceptibility increases slightly.

-

4.

Alloying with silicon reduces the resistance to intercrystalline corrosion.

-

5.

Vacuum melts are somewhat more resistant to intercrystalline corrosion than open melts.

Similar content being viewed by others

Additional information

Central Scientific Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 10–13, November, 1968.

Rights and permissions

About this article

Cite this article

Savkina, L.Y., Fel'dgandler, E.G. Effect of alloying on the susceptibility to intercrystalline corrosion of steel 000Kh16N15M3. Met Sci Heat Treat 10, 857–860 (1968). https://doi.org/10.1007/BF00649209

Issue Date:

DOI: https://doi.org/10.1007/BF00649209