Conclusions

-

1.

Elongated sections of interaction centers are formed at microprotrusions during pressure welding.

-

2.

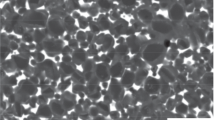

The fractures of copper-nickel joints are characterized by dimples. At low welding temperature (700°C) the fracture is slightly dimpled, while at higher temperatures (850°C) it is distinctly dimpled, as in fractures of the solid metals.

Similar content being viewed by others

Literature cited

V. V. Abramov, E. S. Karakozov, and V. A. Petrov, Fiz. i Khim. Obrabotki Mat., No. 4 (1970).

É. S. Karakozov, B. A. Kartashkin, and M. Kh. Shorshorov, Fiz. i Khim. Obrabotki Mat., No. 3 (1963).

A. P. Semenov, Hardening of Metals [in Russian], Mashgiz, Moscow (1958).

L. G. Orlov and L. M. Utevskii, Zavod. Lab.,25, No. 9 (1969).

Additional information

All-Union Scientific-Research Institute of Medical Instrument Construction. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 74–75, January, 1973.

Rights and permissions

About this article

Cite this article

Abramov, V.V. The structure of fractures in copper-nickel joints produced by pressure welding. Met Sci Heat Treat 15, 81–82 (1973). https://doi.org/10.1007/BF00648469

Issue Date:

DOI: https://doi.org/10.1007/BF00648469