Abstract

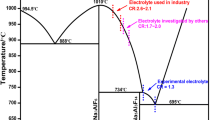

The electrolysis of Al2S3 has been investigated in AlCl3-MgCl2-NaCl-KCl melts. Experimental results obtained at 1023 K show that dissolved Al2S3 can be electrolysed to give aluminium and elemental sulphur. It has been found that the limiting current density for the electrolysis of Al2S3 in these melts is that at the anode and it increases with increasing Al2S3 concentration. It appears that within the current density range 0.2 to 1.2 A cm−2, the cathodic current efficiency of the electrolysis of 5 wt % Al2S3 does not vary significantly with the current density. Within that current density range, current efficiencies of about 75 to 85% are obtained.

Similar content being viewed by others

References

J. C. Agarwal and J. R. Sinek, in ‘Energy: Use and Conservation in the Metals Industry’, (edited by Y. A. Chang, W. M. Danver, and J. M. Cigan), The Metallurgical Society of AIME, New York (1975) p. 121.

Aluminium Industry Continues to Cut Energy Uses,J. Metals 32(8) (1980) 6.

A. S. Russell,Metall. Trans. B 12 (1981) 203.

Arthur D. Little, Inc., ‘A Survey of Potential Processes for the Manufacture of Aluminium’, Argonne National Laboratory Report ANL/OEPM-79-4 (December 1979).

R. O. Loutfy, R. Keller, and G. M. Cook, ‘Preliminary Thermodynamic Assessment of Processes to Produce Aluminium Using Aluminium Sulfide as an Intermediate Product’, Argonne National Laboratory Report ANL/OEPM-78-5 (September 1979).

A. Bucherer, German Patent No. 63,995 (July, (1892).

Aluminium Industrie A.-G., German Patent No. 68,909 (May, 1893).

P. Röntgen and H. Borchers,Metallwirtschaft 12 (1933) 431.

E. I. Khazanov and A. I. Belyaev,Legk. Met. 4 (1935) 1.

E. I. Khazanov and N. I. Komarov,Tsvetn. Metall. 2 (1940) 68.

P. Röntgen and K. Giesen, in ‘Abhadlungen Institut für Metallhüttenwesen und Elektrometallurgie der Technischen Hochschule, Aachen’, Vol. V (edited by W. Borchers) Aachen (1940).

New Process from Japan,Metal Bull. June 4 (1976) 19.

N. Q. Minh, R. O. Loutfy, M. Krumpelt and N. P. Yao,J. Electrochem. Soc. submitted.

N. Q. Minh, R. O. Loutfy, M. Blander and N. P. Yao,Metall. Trans. submitted.

H. Ichikawa and T. Iuchi, in ‘Light Metals 1979’, Vol. l (edited by W. S. Peterson), The Metallurgical Society of AIME, New York (1979) p. 363.

K. Grjotheim and B. J. Welch, ‘Aluminium Smelter Technology: A Pure and Applied Approach’, Aluminium-Verlag GmbH, Düsseldorf (1980).

W. E. Haupin, US Patent No. 3,755,099 (August, 1973).

N. Q. Minh, unpublished results.

N. Q. Minh, R. O. Loutfy and N. P. Yao,J. Electroanal. Chem. Interfac. Electrochem. 131 (1982) 229.

M. J. Ferrante and R. A. McCune, ‘High Temperature Enthalpy and X-Ray Powder Diffraction Data for Aluminium Sulfide (Al2S3)’, Bureau of Mines Report of Investigation 8526, US Department of the Interior, Washington, DC (1981).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Minh, N.Q., Loutfy, R.O. & Yao, N.P. The electrolysis of Al2S3 in AlCl3-MgCl2-NaCl-KCl melts. J Appl Electrochem 12, 653–658 (1982). https://doi.org/10.1007/BF00617485

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00617485