Abstract

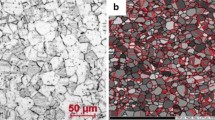

An austenitic flake graphite grey iron in the as-cast condition (AC) was laser surface melted (LSM), and the AC and LSM irons were shot peened (ACp and LSMp). The irons were eroded in distilled water and 0.02% and 3.0% NaCl waters at 50 °C using a 20 kHz, 15 μm peak-to-peak amplitude, ultrasonic device capable of electrochemical measurements. Laser surface melting eliminated the graphite flakes and formed a crack-free uniform layer of predominantly fine austenite and some martensite. The hardnesses of the AC, ACP, LSM, and LSMp irons were 200, 350, 700, and 750 HV, respectively. In distilled water, the erosion rate of the AC iron was reduced by factors of 0.80, 0.05, and 0.04, for the ACp, LSM, and LSMp materials, respectively. In salt water the corrosion rate was increased, and the corrosion-enhanced erosion rates of the AC, ACp, LSM, and LSMp materials were fractions 0.26, 0.16, 0.75, and 0.75, respectively, of the total erosion rate. Corrosion was highest in the irons containing graphite, but the effect of corrosion on the erosion rate was highest in the irons that did not contain graphite. Results of detailed metallographic examination are presented, and the mechanism of cavitation erosion damage is discussed.

Similar content being viewed by others

References

J. M. Hobbs, ASTM Special Technical Publication 408 (American Society for Testing and Materials, Philadelphia, Pennsylvania, 1967) p. 159.

W. J. Tomlinson and.M. G. Talks,Tribol. Int.22 (1989) 195.

Idem, Wear129 (1989) 215.

C. Allen, A. Ball, andB. E. Protheroe,ibid.74 (1982) 289.

W. J. Tomlinson, R. T. Moule andG. N. Blount,ibid.118 (1987) 233.

H. Flgge, “Materials for Cylinder Liners”, SAE International Congress Exposition, Detroit, Michigan, 29 February to 4 March 1988, SAE paper 880096.

Anon, GKN Engine Parts Publicity Department, Brochure on cylinder liner product range, GKN Sheepbridge Stokes, Chesterfield, UK.

R. Beeching,Prod. Engng19 (1948) 110.

W. J. Rheingans,Trans. ASME72 (1950) 705.

P. H. Black,Met. Engng Q.12 (1972) 46.

G. Fair, B. Noble, andR. B. Waterhouse, in “Advances in Surface Treatments”, Vol. 1, edited by A. Niku-Lari (Pergamon, Oxford, 1984) p. 3.

A. J. Gould andU. R. Evans,J. Irón Steel Inst. London160 (1948) 164.

M. Takemoto andT. Shimohara, in “Advances in Surface Treatments”, Vol. 1, edited by A. Niku-Lari (Pergamon, Oxford, 1984) p. 127.

N. Groseman,ASTM Bull.183 (1952) 61.

J. M. West, “Basic Corrosion and Oxidation”, 2nd Edn (Ellis Horwood, Chichester, 1986).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tomlinson, W.J., Talks, M.G. Shot peening, laser surface melting and the cavitation erosion of an austenitic grey iron. J Mater Sci 26, 804–808 (1991). https://doi.org/10.1007/BF00588319

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00588319