Abstract

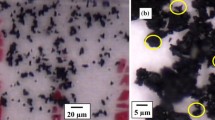

The fracture surface morphology of various thermoplastic rubber and rubber vulcanizates based on natural rubber (NR), ethylene propylene diene rubber (EPDM), nitrile rubber (NBR), polyethylene (PE) and polypropylene (PP), namely NR-PE, NR-PP, EPDM-PE, EPDM-PP and NBR-PP, has been studied over a range of blend ratios, levels of interaction, rates, temperatures and modes of testing. The fracture surface changes with changes in blend ratio. Incorporation of a third component like EPDM or chlorinated polyethylene (CPE) to a certain percentage does not change the fracture morphology. Sulphur curing in the NR-PE blend generates a ductile matrix like rubber whereas large fissures are observed for peroxide-cured systems. Modification of both rubber and plastic also changes the surface morphology. The samples tested at various temperatures, rates and modes show similar features on the fracture surface.

Similar content being viewed by others

References

A. K. Bhowmick,Kautschuk Gummi Kunststoffe 37 (1984) 191.

A. Saha Deuri andA. K. Bhowmick,J. Mater. Sci. 22 (1987) 4299.

A. Y. Coran, in “Handbook of Elastomers — New Development and Technology”, edited by A. K. Bhowmick and H. L. Stephens (Dekker, New York, 1988) p. 249.

D. J. Elliott andA. J. Tinker, in Proceedings, “Thermoplastic Natural Rubber Blends,” International Rubber Conference, Kuala Lumpur, 1985.

N. Roy Choudhury andA. K. Bhowmick,J. Mater. Sci. 23 (1988) 2187.

Idem, J. Appl. Polym. Sci. 38 (1989) 1091.

Idem, J. Adhesion Sci. Technol. 2 (1988) 167.

Idem, J. Mater. Sci. 25 (1990) 161.

P. I. Vincent, in “Encyclopedia of Polymer Science and Technology”, Vol. 7, edited by N. M. Bikales (Interscience, New York, 1967) p. 292.

A. K. Bhowmick et al., Rubb. Chem. Technol. 53 (1980) 327.

A. K. Bhowmick, S. Basu andS. K. De,ibid. 53 (1980) 321.

A. Saha Deuri andA. K. Bhowmick,J. Appl. Polym. Sci. 35 (1988) 327.

A. K. Bhowmick,J. Mater. Sci. Lett. 5 (1986) 1042.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Roy Choudhury, N., Bhowmick, A.K. Micromechanism of failure of thermoplastic rubber. J Mater Sci 25, 2985–2989 (1990). https://doi.org/10.1007/BF00584915

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00584915