Summary

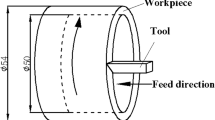

The investigation included the planning and realization of a model wear-test system which enabled the cutting process during turning with ultra-hard non-metallic cutting materials to be simulated, taking into account the main tribological parameters.

Initial results for friction tests with differing ultra-hard materials against various ferrous and non-ferrous metals show good agreement between the simulated wear morphologies and those observed in the real cutting process.

Similar content being viewed by others

References

Habig KH (1980) Verschleiß und Härte von Werkstoffen. Hanser Verlag, München

Johnson RL, Buckley DH (1967/68) Lubrication and wear fundamentals for high-vacuum applications. Proc Inst Mech Engrs 182 Pt 3 A, pp 479–490

Kordon MJ (1967) Adhesion and cohesion of metals in high-vacuum. ASTM-STP 431:109–127

Czichos H (1972) The mechanism of the metallic adhesion bond. Appl Phys 5:1890–1896

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Koenig, W., Boemcke, A. Wear mechanisms of ultra-hard non-metallic cutting materials. Z. Anal. Chem. 333, 461–465 (1989). https://doi.org/10.1007/BF00572353

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00572353