Abstract

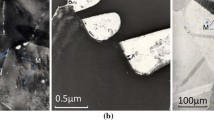

The contribution of grain size and precipitation hardening to the yield stress and other mechanical properties was investigated. An alloy of iron with 1 % copper was prepared as supersaturated solid solution with grain sizes between 12 and 140 μm. By ageingat 500 and 600° C different precipitation hardening conditions were produced.

For small particle sizes an additive behaviour of grain-boundary and precipitation hardening was found (particle radiusr < 50 Å). For large particle sizes the yield stress is independent of grain size (r > 150 Å). A transition is found for intermediate particle sizes with grain size dependence for small and independence for large grain sizes (50 Å <r < 150 Å).

The effect of grain boundaries and particles on the formation and motion of dislocations is used to explain this behaviour.

Similar content being viewed by others

Abbreviations

- σy :

-

measured yield stress

- Δσ :

-

increase in yield stress

- Δσ p :

-

particle hardening

- Δσ b :

-

grain-boundary hardening

- δσ s :

-

solid solution hardening

- σ α-Fe:

-

yield stress of a pure α-Fe crystal

- σ 0 :

-

yield stress of the alloy atD −1/2=0≡ D=∞

- D :

-

grain size

- k y :

-

slope of Hall-Petch-relation

- b :

-

Burgers vector

- ε :

-

plastic strain

- ρ y :

-

dislocation density at 0.2 % strain

- ρ b :

-

density of dislocation generated at grain boundaries

- ρ s :

-

dislocation density from second sources

- ρ p :

-

density of dislocations generated at particles

- λ :

-

average free path of dislocation

- G :

-

shear modulus

- α:

-

constant factor relatingΔσ andρ

- σu :

-

ultimate tensile strength

References

D. Peckner, “The Strengthening of Metals” (Reinhold, London, 1964).

E. Hornbogen (ed.), “Werkstoffe mit hoher Festigkeit”, to be published (Stahl und Eisen, Düsseldorf, 1974).

G. Staniek andE. Hornbogen,Scripta Met. 7 (1973) 615.

E. Hornbogen, in “Steel Strengthening Mechanisms” (Climax Molybdenum Cor., Greenwich, Conn., 1970).

A. J. E. Foreman andM. J. Makin,Canad. J. Physics 45 (1967) 511.

E. Hornbogen andR. C. Glenn,Trans. Met. Soc. AIME 218 (1960) 1064.

H. A. Wriedt andL. S. Darken,ibid 218 (1960) 30.

E. Hornbogen,Trans. ASM 57 (1964) 120.

E. Orowan, “Symposium on Internal Stresses in Metals and Alloys” (Institute of Metals, London, 1948) 451.

N. J. Petch,J. Iron Steel Inst. 174 (1953) 25.

H. Conrad, in “Reinststoffprobleme”, Vol. IV (edited by M. Balarin) (Akademie-Verlag, Berlin, 1972) p. 409.

A. H. Keh andS. Weissman, “Electron Microscopy and Strength of Crystals”, (edited by G. Thomas and J. Washburn) (Wiley, New York, 1963).

N. Igata andS. Seto, Proceedings ICSTIS,Suppl. Trans. ISIJ,11 (1971) 1293.

G. Bäro andE. Hornbogen, “Quantitative Relation between Properties and Microstructure” (edited by D. G. Brandon and A. Rosen) (Israel University Press, Jerusalem, 1969) p. 457.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hornbogen, E., Staniek, G. Grain-size dependence of the mechanical properties of an age-hardening Fe-1 % Cu-alloy. J Mater Sci 9, 879–886 (1974). https://doi.org/10.1007/BF00570379

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00570379