Abstract

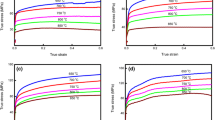

The constitutive behaviour of α-β nickel silver in the temperature range 600–850 °C and strainrate range 0.001–100s−1 was characterized with the help of a processing map generated on the principles of the dynamic materials model. On the basis of the flow-stress data, processing maps showing the variation of the efficiency of power dissipation (given by [2m/(m+1)], wherem is the strain-rate sensitivity) with temperature and strain rate were obtained, α-β nickel silver exhibits a single domain at temperatures greater than 700 °C and at strain rates lower than 1 s−1 with a maximum efficiency of power dissipation of about 42% occurring at about 850 °C and at 0.1 s−1. In the domain, the α phase undergoes dynamic recrystallization and controls the deformation of the alloy, while the β phase deforms superplastically. Optimum conditions for the processing of α-β nickel silver are 850 °C and 0.1 s−1. The material undergoes unstable flow at strain rates of 10 and 100 s−1 and in the temperature range 600–750 °C, manifestated in the form of adiabatic shear bands.

Similar content being viewed by others

References

D. Padmavardhani andY. V. R. K. Prasad,Metall. Trans. 22A (1991) 2996.

Idem, J. Mater. Sci.28 (1993) 0000

K. J. Anusavice andR. T. Dehoff,Metall. Trans. 3A (1972) 1279.

R. D. Schelleng andG. H. Reynolds,ibid. 4A (1973) 2199.

D. W. Livesey andN. Ridley,ibid. 9A (1978) 519.

Idem, ibid. 13A (1982) 1619.

D. W. Livesey andN. Ridley,Metall. Sci. 16 (1982) 563.

Idem, J. Mater. Sci. 19 (1984) 3602.

M. Cook,J. Inst. Metals 66 (1) (1938) 139.

D. M. Ward andB. J. Helliwell,ibid. 98 (1970) 98.

Y. V. R. K. Prasad, H. L. Gegel, S. M. Doraivelu, J. C. Malas, J. T. Morgan, K. A. Lark andD. R. Barker,Metall. Trans. 15A (1984) 1883.

H. L. Gegel, J. C. Malas, S. M. Doraivelu, V. A. Shende, in “Metals Handbook”, 9th Edn, Vol. 14 (ASM International, Metals Park, OH, 1987) p. 417.

J. M. Alexander, in “Modelling of Hot Deformation of Steels”, edited by J. G. Lenard (Springer, Berlin, 1989) p. 101.

A. K. S. Kalyan Kumar, MSc (Engng) thesis, Indian Institute of Science, Bangalore, India 1987

Y. V. R. K. Prasad,Indian J. Tech. 28 (1990) 435.

H. Ziegler, in “Progress in Solid Mechanics”, edited by I. N. Sneddon and R. Hill (North-Holland, Amsterdam, 1963) p. 93.

K. Laue andH. Stenger, in “Extrusion” (ASM, Metals Park, OH, 1981) p. 109.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Padmavardhani, D., Prasad, Y.V.R.K. Processing maps for hot working of Cu-Ni-Zn alloys. J Mater Sci 28, 5275–5279 (1993). https://doi.org/10.1007/BF00570078

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00570078