Abstract

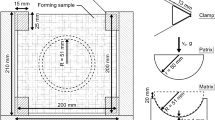

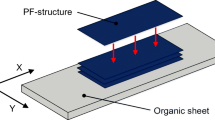

In this investigation a mould with hemispherical cavity and 80 kN hydraulic press, allowing variable stamping speeds, are employed for experimentally studying of the 3-D stamp forming process of continuous fiber reinforced thermoplastic laminates. In particular, glass fiber (GF) reinforced polyetherimide (PEI) woven fabric made of sheath surrounded, polymer powder impregnated fiber bundles manufactured by Enichem, Italy, is used. Pre-consolidated laminates are heated by contact heating in an external heater up to about 120°C above the glass transition temperature (T g) of the polymer matrix; they are then stamp formed in a cold matched metal tool. Typical cycle times (including preheating time of the preconsolidated laminates) are in the range of 3 min. Useful processing conditions, such as stamping temperature, stamping velocity and hold-down pressure required for stamp forming of this composite are determined. In addition the effect of die geometries (deformation radian) and original laminate dimensions are studied. The results describe the correlations between processing parameters and fiber buckling. Finally the thickness distribution in stamped parts are investigated in relation to different directions of fiber orientation.

Similar content being viewed by others

References

Stolze, R., ‘Verstärkungsfasern und Matrixmaterialien für Hochleistungsverbundwerkstoffe’,Kunststoffe 77 (11) 1987, 1157–1160.

Becker, H. J., ‘Fertigung von Automobilteilen durch Faserwickelverfahren und Bandlegetechnik’,Magazin Neue Werkstoffe 4, 1988, 31–34.

Borgschulte, K., ‘Faserwickeln mit Prepregs und GMT-Verarbeitung’,Plastverarbeiter 39, 1989, 7–1.

Robertson, R. E., Hsiue, E. S., Sickafus, E. N., and Yeh, G. S. Y., ‘Fiber Rearrangements During the Molding of Continuous Fiber Composites: I. Flat Cloth to a Hemisphere’,Polymer Composites 2, 1981, 126–131.

Mallon, P. J. and Pipes, R. B., ‘Polymeric Diaphragm Forming of Continuous Fiber Reinforced Thermoplastics’,33rd International SAMPE Symposium, March 7–10, 1988.

Hou, M. and Friedrich K., ‘Stamp Forming of Continuous Carbon Fiber/Polypropylene Composites’,Composites Manufacturing 2, 1991, 3–9.

Hou, M. and Friedrich, K. ‘Thermoforming of High Performane Composites with Thermoplastic Matrices’,Engineering Plastics,5, 1992, 86–100.

Suemasu, H., Friedrich, K. and Hou, M., ‘On Deformation of Woven Fabric Reinforced Thermoplastic Composites during Stamp-Forming’,Composites Manufacturing.

Witzler, S. ‘Pressure-molding Methods for Thermoplastic Composites’,Advanced Composites, 1988, 49–53.

Monaghan, M. R., Mallon, P. J., O'Rádaigh, C. M. and Pipes, R. B., ‘The Effect of Diaphragm Stiffness on the Quality of Diaphragm Formed Thermoplastic Composite Components’,Journal of Thermoplastic Composite Materials 3, 1990, 202–215.

Scherer, S. and Friedrich, K. ‘Experimental Background for Finite Element Analysis of the Interply-slip Process during Thermoforming of Thermoplastic Composites’,Developments in the Science and Technology of Composite Materials, Fourth European Conference on Composite Materials, Sept. 25–28, 1990. Stuttgart, F.R.G., 1001–1006.

Barnes, J. A. and Cogswell, F., ‘Transverse Flow Processes in Continuous Fiber-Reinforced Thermoplastic Composites’,Composites 20 (1), 1989, 38–42.

Potter, K. D., ‘The Influence of Accurate Stretch Data for Reinforcements on the Production of Complex Structural Mouldings’,Composites (1979), 161–173.

O'Brádaigh, C. M. and Pipes, R. B., ‘Issues in Diaphragm Forming of Continuous Fiber Reinforced Thermoplastic Composites’,Polymer Composites 12, 1991, 246–256.

Hou, M., ‘Zum Thermoformen und Widerstandsschweißen von Hochleistungsverbundwerkstoffen mit thermoplastischer Matrix’, Dissertation at the University of Kaiserslautern, Germany, D 386, 1993.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hou, M., Friedrich, K. 3-D stamp forming of thermoplastic matrix composites. Appl Compos Mater 1, 135–153 (1994). https://doi.org/10.1007/BF00567575

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00567575