Abstract

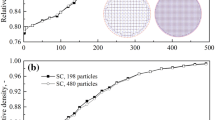

A known approach to mathematical description of the compaction process for monodispersed spherical powders under hot isostatic compression is developed for actual polydispersed powders. Calculated compaction curves for silicon nitride agree satisfactorily with experimental data. Estimation of grain-boundary diffusion parameters gives values of 6 · 10−18 m3/sec and 180 kJ/mole which corre-spond to results obtained in other experimental works.

Similar content being viewed by others

Literature cited

A. S. Helle, K. E. Easterling, and M. F. Ashby, ”Hot-isostatic pressing diagrams: new developments,” Acta Met.,33, No. 12, 2163–2174 (1985).

V. A. Ivensen, Phenomenology of Sintering [in Russian], Metallurgiya, Moscow (1985).

R. A. Andreevskii, Yu. S. Konyaev, M. A. Leont'ev, and G. I. Pivovarov, ”Effect of high pressure on the structure and properties of silicon nitride,” Proc. XI Internat. Conf. ”High pressures ln science and technology,” Naukova Dumka, Kiev (1987).

R. A. Andreevskii, M. A. Leont'ev, and A. V. Bragin, ”Temperature dependence of compaction with sintering of silicon nitride,” Izv. Akad. Nauk SSSR, Neorg. Mater.,20, No. 12, 2055–2056 (1984).

F. Thümmler, ”Sintering and high-temperature properties of Si3N4 and SiC,” in: Sintering Process, Plenum Press, N.Y. (1980).

K. P. Kunz, V. K. Sarin, R. F. Davis, et al., ”Self-diffusion of silicon-30 and nitrogen-15 in α-phase silicon nitride,” Mater. Sci. Eng.,A109, 23–28 (1989).

Additional information

Moscow Institute of Fine Chemical Technology. Translated from Poroshkovaya Metallurgiya, No. 4(364), pp. 20–24, April, 1993.

Rights and permissions

About this article

Cite this article

Vol'dman, G.M., Leont'ev, M.A. Possible approach to quantitative description of the compaction process with hot isostatic pressing of polydispersed materials. Powder Metall Met Ceram 32, 299–302 (1993). https://doi.org/10.1007/BF00560013

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00560013