Abstract

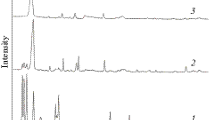

Samples of highly dispersed tungsten carbide powders of various origins were obtained by electrical-discharge sintering. The specimens were 8 mm in diameter, 5 mm in height and had a grain size of 1 µm, density 15.5–15.8 g/cm3, hardness 92–93 HRA, and cracking resistance 6–8 MPa·m1/2. The structure and phase composition of the sintered samples was not observed to change appreciably from those of the initial powder. The salient features of electrical-discharge sintering of tungsten carbide power are described.

Similar content being viewed by others

References

A. I. Raichenko, Foundations of Sintering of Powders by Passage of an Electric Current [in Russian], Metallurgiya, Moscow (1987).

V. N. Shapoval, Kh. B. Kushkov, and I. A. Novoselova, “High-temperature electrochemical synthesis of tungsten carbide,” Zh. Prikl. Khim.,58, No. 5, 1027–1030 (1980).

V. N. Shapoval, Kh. B. Kushkov, and I. A. Novoselova, “Thermodynamic substantiation of electrochemical synthesis of tungsten, molybdenum, and boron carbides,” Ukr. Khim. Zh.,48, No. 7, 733–742 (1982).

A. S. Petukhov, I. V. Uvarova, V. P. Bondarenko, et al., “Laws of low-temperature synthesis of carbides of tungsten and a WC—Co mixture in a methane—hydrogen gas medium,” Poroshk. Metall., No. 10, 31–35 (1992).

O. N. Grigor'ev, Kh. B. Kushkov, A. M. Shatokhin, et al., “Properties of highly dispersed tungsten carbide powders obtained by high-temperature electrochemical synthesis,” Poroshk. Metall., No. 18, 1–4 (1991).

A. G. Evans and E. A. Charles, “Fracture toughness determinations by indentation,” J. Am. Ceram. Soc.,59, Nos. 7–8, 371–372 (1977).

G. R. Anstis, P. Chanticul, B. R. Lawn, and D. B. Marshall, “A critical evaluation of indentation for measuring fracture toughness. I. Direct crack measurements,” J. Am. Ceram. Soc.,64, No. 9, 533–538 (1981).

Additional information

Institute of Materials Sciences, Ukrainian Academy of Sciences Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 9–10, pp. 17–20, September–October, 1995.

Rights and permissions

About this article

Cite this article

Popov, V.P., Shatokhin, A.M., Raichenko, A.I. et al. Structure and properties of tungsten carbide obtained by electric-discharge sintering of a disperse powder. Powder Metall Met Ceram 34, 505–507 (1996). https://doi.org/10.1007/BF00559957

Issue Date:

DOI: https://doi.org/10.1007/BF00559957