Abstract

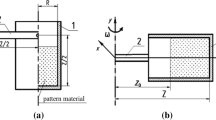

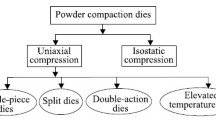

A new compaction method uses a porous female die made of powdered materials without plasticizer. Powders alloyed with carbon, nickel, chromium, molybdenum, and microtalc were used to produce the porous die. The powder was compacted by a special device, in which the operating surface of the matrix was lubricated through the open pores of the powdered material. Compaction of materials into a porous die ensures highly efficient drainage of gases from the press mold. As a result the density of iron-based compacts increases to 7.4–7.7 g/cm3 and in regard to mechanical properties the sintered materials can compete with those obtained by hot forging.

Similar content being viewed by others

References

A. T. Mamedov, “Development of a technology of compaction of increased-density parts using gas drainage methods. III. Influence of technological and solid lubricants on the properties of powder materials,” Poroshk. Metall., No. 9/10, 4 (1994).

A. T. Mamedov, V. V. Rumyantsev, and D. A. Bagirov, “Press mold for compacting powder products in the form of a shell,” Favorable decision on invention, February 16, 1992. Application No. 4815502/02 (044352).

“Inventor's Certificate 1749302 USSR. Wear-resistant sintered iron-based material,” Otkr. Izobret., No. 27 (1993).

I. L. Knunyashch (ed.), Encyclopedic Chemical Dictionary [in Russian], Sov. Entsyklopedia, Moscow (1983).

I. M. Fedorchenko, I. N. Frantsevich, I. D. Radomysel'skii, et al., Powder Metallurgy. Materials, Technology, Properties, and Applications [in Russian], Nauk. Dumka, Kiev (1985).

Additional information

NPO “Bakkonditsioner” (Scientific-Industrial Firm Bakkonditsioner), Baku. Translated from Poroshkovaya Matallurgiya, No. 11–12, pp. 1–6, November–December, 1994.

Rights and permissions

About this article

Cite this article

Mamedov, A.T. Development of a technology of compaction of increased-density parts using gas drainage methods. IV. Compaction of powder materials without plasticizer. Powder Metall Met Ceram 33, 559–562 (1995). https://doi.org/10.1007/BF00559658

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00559658