Abstract

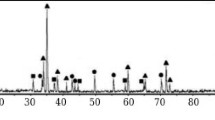

The effect of additions of scandium oxide (1, 5, and 10 vol. %) on compaction during sintering of a disperse mixture of W-Sc2O3 powder at 2000°C has been studied. It has been found that the scandium oxide particles activate compaction during heating and conversely retard shrinkage of tungsten in the stage of isothermal soaking. The kinetics of compaction during sintering is determined by the geometry of the heterophase system. Depending on how much the tungsten and scandium oxide particles increase in size, the nature of thestructure changes markedly from matrix-statistical to statistical.

Similar content being viewed by others

References

O. I. Get'man, A. E. Korol'kov, S. P. Rakitin, et al., “Evolution of the structure of a porous metal cathode with a tungsten skeleton during use,” Élektron. Tekh. Mater., No. 5, 17 (1991).

N. M. Sbrockey and D. L. Johnson, “Influence of second phase particle to retard smoothing and sintering,” Sintering Processes: Proceedings of Fifth International on Sintering and Related Phenomena, Plenum, New York (1979), pp. 177–186.

V. V. Panichkina and L. D. Konchakovskaya, “Study of the process of compaction during sintering of dispersion-hardened molybdenum alloys,” in: Composites [in Russian], Nauka, Moscow (1981).

V. V. Skorokhod and S. M. Solonin, Physical-Metallurgical Fundamentals of Powder Sintering [in Russian], Metallurgiya, Moscow (1984).

Ya. E. Geguzin, Physics of Sintering [in Russian], Nauka, Moscow (1984).

K. I. Portnoi and N. I. Timofeeva, Oxygen Compounds of Rare-Earth Elements [in Russian], Metallurgiya, Moscow (1986).

G. A. Semenov, “Mass-spectrometric study of the evaporation of scandium oxides,” Zh. Neorg. Khim.,10, No. 10, 2390 (1965).

C. H. Hsuen and A. G. Evans, “Microstructure evolution during sintering: the role of evaporation-condensation,” Acta. Met.31, 189 (1983).

Ya. I. Dutchak, Molecular Physics [in Ukrainian], Vid. L'vyv. Univ. L'vyv (1973).

V. V. Skorokhod, Yu. M. Solonin, and I. V. Uvarova, Chemical, Diffusion, and Rheological Processes in the Technology of Powder Materials [in Russian], Nauk. Dumka, Kiev (1990).

Additional information

Institute of Problems in Materials Science, National Academy of Sciences of Ukraine, Kiev. Translated from Poroshkovaya Metallurgiya, Nos. 11/12(382), pp. 10–15, November–December, 1995.

Rights and permissions

About this article

Cite this article

Get'man, O.I., Panichkina, V.V. & Skorokhod, V.V. Sintering a disperse mixture of W-Sc2O3 powders. Powder Metall Met Ceram 34, 595–599 (1996). https://doi.org/10.1007/BF00559486

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00559486