Abstract

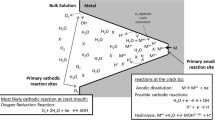

A model of electrochemical processes near a crack tip in a stressed metal subjected to corrosion with hydrogen depolarization is suggested. It is shown that, in order to describe the kinetics of hydrogenation of the prefracture area, it is necessary to take into account the type of passivation layer on the newly formed metal surface near the crack tip and the mechanism of its formation. The model was applied to an iron-water system whose pH value is lower than that of hydrate formation. As a result, we determined the nonstationary potential of the metal-electrolyte interface as a function of the parameters of the stress-strain state near a crack tip and characteristics of the metal.

Similar content being viewed by others

References

H. Kaesche,Metal Corrosion. Physico-Chemical Principles and Actual Problems [Russian translation], Metallurgiya, Moscow (1982).

T. Zakroczymski, “Penetration of electrolytic hydrogen into iron and steel and its effect on the mechanical properties of metals,”Zashch. Met., No. 5, 733–739 (1983).

N. P. Zhuk,A Course in Corrosion Theory and Protection of Metals [in Russian], Metallurgiya, Moscow (1976).

R. P. Ganglöff, “Crack tip modelling of hydrogen environment embrittlement; application to fracture mechanics life predictions,”Mater. Sci. Eng. A103, No. 1, 157–166 (1988).

L. N. Petrov, “On the mechanism of local corrosion in corrosion cracks,”Fiz.-Khim. Mekh. Mater. 26, No. 4, 3–8 (1990).

V. V. Panasyuk, L. V. Ratych, and I. M. Slobodyan, “Evaluation of the efficiency of inhibitor protection of steels against corrosion-mechanical fracture,”Fiz.-Khim. Mekh. Mater.,22, No. 3, 3–15 (1986).

V. I. Pokhmurskii, É. I. Lychkovskii, V. M. Filatov, and I. P. Gnyp, “Distribution of the potential in narrow slots that simulate electrochemical conditions in the cavities of corrosion cracks,”Fiz.-Khim. Mekh. Mater.,23, No. 4, 27–30 (1987).

I. M. Dmytrakh, “Effect of tensile stresses on the parameters of corrosion processes in model crack-slots,”Fiz.-Khim. Mekh. Mater.,26, No. 4, 22–25 (1990).

H.-J. Rätzer-Sheibe, “Repassivation kinetics and anodic oxide growth of titanium and titanium alloys in aqueous electrolytes,” in:Proceedings of the 8th International Congress on Metallic Corrosion, Vol. 1 (1981), pp. 212–219.

M. J. Avrami,Chem. Phys.,7, 1103 (1939) (cited according to [9]).

A. V. Fishgoit, T. N. Zueva, N. T. Bychkov, and L. F. Kurnosova, “Kinetics of electrolytic hydrogenation of nickel alloys affected by plastic strains,”Fiz.-Khim. Mekh. Mater.,24, No. 3, 42–47 (1988).

T. R. Beck,J. Electrochem. Soc.,115, 890 (1968) (cited according to [9]).

X. G. Zhang and J. Verechen, “Breakdown and formation processes of titanium oxide film during straining in aqueous electrolyte,”NATO ASI Series. Chemistry and Physics of Fracture, Ser. E, No. 130, 678–681 (1987).

F. P. Ford, “Three mechanisms of environmentally assisted cracking,”Int. J. Press. Ves. Piping, No. 40, 343–362 (1989).

É. M. Gutman,Mechanical Chemistry of Metals and Protection against Corrosion [in Russian], Metallurgiya, Moscow (1961).

R. M. McMeeking, “Finite deformation analysis of crack tip opening in elastic-plastic materials and implications for fracture,”J. Mech. Phys. Solids,25, No. 5, 357–381 (1977).

V. V. Panasyuk, A. E. Andreikiv, and V. S. Kharin, “A model of crack propagation in strained steels affected by hydrogen,”Fiz.-Khim. Mekh. Mater.,23, No. 2, 3–17 (1987).

V. V. Panasyuk, A. E. Andreikiv, and O. I. Obukhivskii, “Computation model of crack propagation in metals affected by hydrogen,”Fiz.-Khim. Mekh. Mater.,20, No. 3, 3–6 (1984).

Additional information

Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fiziko-Khimicheskaya Mekhanika Materialov, Vol. 30, No. 1, pp. 25–29, January–February, 1994.

Rights and permissions

About this article

Cite this article

Andreikiv, O.E., Tym'yak, N.I. Electrochemical model of local corrosion at the tip of a loaded crack. Mater Sci 30, 19–24 (1995). https://doi.org/10.1007/BF00559011

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00559011