Abstract

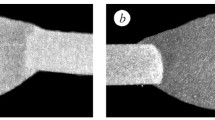

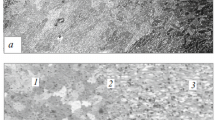

The corrosion behavior of homogeneous and heterogeneous (with 12Kh18N10T and St 3 steels) welded joints of 06Kh18G9N5AB steel in boiling chloride and alkali solutions and in NACE solution is investigated. The influence of welding methods and electrodes on the structure and distribution of alloying elements in the areas around the welded joints is demonstrated.

Similar content being viewed by others

References

N. I. Kakhovskii,Welding of Stainless Steels [in Russian], Tekhnika, Kiev (1986).

Corrosion-Resistant Steels and Alloys for the Equipment and Pipe Systems of Nuclear Power Stations [in Russian], R. K. Melekhov (ed.), Naukova Dumka, Kiev (1983).

G. V. Fenik, V. N. Pavlov, I. I. Vasilenko et al., “Corrosion behavior of austenitic 06Kh18G9N5AB chromium-manganese-nickel steel and 07Kh13AH20 chromium-manganese steel,”Fiz.-Khim. Mekh. Mater., No. 6, 46–51 (1985).

D. A. Prokoshkin, I. F. Zudin, R. S. Sharipkulov, and O. A. Bannykh,Alloying of Chromium-Manganese Stainless Steel [in Russian], Izd. Akad. Nauk SSSR, Moscow (1961).

V. G. Beletskii, V. P. Loginov, M. N. Obraztsova, and V. N. Pavlov, “Features of Structural and Phase Changes in 06Kh18G9N5AB Steel under High-Temperature Heating,: in:Shipbuilding Industry, ser. Metal Science and Metallurgy (Collection of papers) [in Russian], issue 2 (1986), pp. 14–15.

N. I. Kakhovskii, K. A. Yushchenko, V. G. Fartushnyi, and Z. V. Yushkevitch, “Welding of Corrosion-Resistant Austenitic Chromium-Nickel-Manganese-Nitrous 07Kh17N5G9AB (ÉP 55) Steel,”Automatic Welding, No. 7, 27–31 (1963).

N. I. Kakhovskii and V. G. Fartushnyi, “Titanium and niobium influence on the structure and properties of chromium-nickel-manganese welded joints,”Automatic Welding, No. 7, 40–43 (1965).

A. I. Shutlin, “Chromium-manganese stainless steel,”Metallurgiya 8, No. 4/5, 8–10 (1933).

N. I. Vasilenko and R. K. Melekhov,Corrosion Cracking of Steels [in Russian], Naukova Dumka, Kiev (1987).

MR 185–86. Strength Calculations and Tests. Methods of Testing Corrosion Cracking Susceptibility for Steels and Alloys in Liquid Media [in Russian], VNIINMASH, Moscow (1986).

P. A. Platonov, I. Ye. Tyrsunov, I. Ye. Levit, et al.,Effect of Hydrogen on Intercrystalline Corrosion of Stainless Austenitic Steels [in Russian], Preprint No. 4087/11, Institute of Nuclear Energy, Moscow (1985).

H.-J. Schuller, “Failures at Weld Seams,”Syst. Anal. Tech. Failures., Oberursel, 327–372 (1986).

D. I. Johnson, D. A. Davis, and W. Washington, “Effect of sensitization on hydrogen transport in austenitic stainless steel,”Scr. Met. 23, No. 3, 321–326 (1989).

Additional information

Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fiziko-Khimicheskaya Mekhanika Materialov, Vol. 29, No. 5, pp. 7–15, September–October, 1993.

Rights and permissions

About this article

Cite this article

Melekhov, R.K., Chumalo, G.V., Pavlov, V.N. et al. Corrosion behavior of welded joints of austenitic 06Kh18G9N5AB steel. Mater Sci 29, 437–445 (1994). https://doi.org/10.1007/BF00558762

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00558762