Abstract

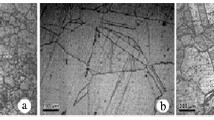

We study the influence of chemical and phase composition on the cyclic crack-growth resistance of non-hydrogenated and hydrogenated welded joints in low-alloy steel at normal and low (−70°C) temperatures. It was discovered that the increase in the nickel content from 0.06% to 3.27% induces an increase in impact toughness and cyclic crack-growth resistance at low temperatures which can be explained by the increase in the content of needle ferrite and by the substitution of uniformly distributed residual austenite for the pearlitic component in the zone characterized by the columnar structure of heat treated beads. Hydrogen saturation of the weld metal leads to a decrease in its cyclic crack-growth resistance at normal temperatures and produces almost no effect on this parameter at low temperatures (−70°C). The presence of the second austenitic phase in the low-alloy weld metal decreases its susceptibility to hydrogen embrittlement in the case where finely divided austenite is uniformly distributed over the weld.

Similar content being viewed by others

References

RD 50-345-82.Methodical Instructions. Strength Analysis and Tests in Machine Building. Methods for Mechanical Testing of Metals. Determination of the Characteristics of Crack-Growth Resistance (Fracture Toughness) under Cyclic Loading [in Russian], Izd. Standartov, Moscow (1983).

V. V. Panasyuk (editor),Fracture Mechanics and Strength of Materials: A Handbook [in Russian], Vol. 4: O. N. Romaniv, S. Ya. Yarema, G. N. Nikiforchin, N. A. Makhutov, and M. M. Stadnik,Fatigue and Cyclic Crack-Growth Resistance of Structural Materials, Naukova Dumka, Kiev (1990).

O. P. Ostash and V. T. Zhmur-Klimenko, “Growth of fatigue cracks in metals at low temperatures (a survey),”Fiz.-Khim. Mekh. Mater.,23, No. 2, 17–29 (1987).

O. P. Ostash, A. F. Degtyarev, and A. B. Kunovskii, “Low-temperature cyclic crack-growth resistance of steels in high-strength state,”Fiz.-Khim. Mekh. Mater.,27, No. 2, 62–67 (1991).

P. McIntyre, “Interaction of hydrogen with steel in the process of cyclic loading,” in:Proceedings of the First Soviet-British Seminar on Corrosion Fatigue of Metals [in Russian], Naukova Dumka, Kiev (1982), pp. 121–147.

C. L. Briant and S. K. Banerji (editors),Treatise on Materials Science and Technology: Vol. 25, Embrittlement of Engineering Alloys, Academic Press, New York (1983).

I. N. Levina,Microstructural Features of the Embrittlement of Structural Stainless Steels and Alloys in the Atmosphere of Hydrogen, Author's Abstract of the Candidate Degree Thesis (Technical Sciences), L'viv (1990).

K. A. Esakul and W. W. Gerberich, “Internal hydrogen degradation of fatigue thresholds in HSLA steel,”Sixteenth National Symposium on Fracture Mechanics (Columbus, Ohio, 1983), Philadelphia, Pa, (1985), pp. 131–148.

Additional information

Karpenko Physicomechanical Institute, Ukrainian Academy of Sciences, L'viv. Translated from Fiziko-Khimicheskaya Mekhanika Materialov, Vol. 31, No. 2, pp. 62–68, March – April, 1995.

Rights and permissions

About this article

Cite this article

Ostash, O.P., Zynyuk, O.D., Pokhodnya, I.K. et al. Low-temperature cyclic crack-growth resistance of hydrogenated welds. Mater Sci 31, 213–218 (1996). https://doi.org/10.1007/BF00558641

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00558641