Conclusions

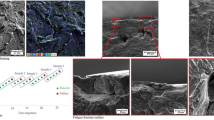

1. Ion-plasma deposition, electrospark alloying and welding can improve the working lives of microsurgical instruments by factors of 2–3.

2. Ion bombardment is promising for strengthening cutting and gripping microsurgical instruments.

Similar content being viewed by others

Literature cited

V. K. Maksimov and N. V. Khabibullina, Major Research Lines in Developing and Producing Medical Instruments [in Russian], Moscow (1986), pp. 155–156.

V. M. Matukhnov, G. I. Altareva, V. I. Kostin, et al., Novosti Med. Tekh., Issue 5, 25–29 (1983).

M. M. Mironov and N. V. Khabibullina, New Medical Instruments [in Russian], Moscow (1984), pp. 25–26.

M. M. Mironov, Major Research Lines in Developing and Producing Medical Instruments [in Russian], Moscow (1986), pp. 157–160.

Additional information

Scientific-Industrial Association “Medinstrument,” Kazan. Translated from Meditsinskaya Tekhnika, No. 2, pp. 24–26, March–April, 1988.

Rights and permissions

About this article

Cite this article

Mironov, M.M., Aver'yanov, V.I. Improving wear resistance in microsurgery instruments by hardening the working parts. Biomed Eng 22, 46–48 (1988). https://doi.org/10.1007/BF00556151

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00556151