Conclusions

1. ESA applied to the working parts of microsurgical gripping instruments has been used with wear-resistant alloys to improve the functions and lengthen the working life.

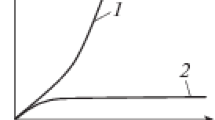

2. The alloy-layer thicknesses for the various materials deposited under the same conditions are substantially dependent on the electrode plasticity.

Similar content being viewed by others

Literature cited

V. K. Maksimov and N. V. Khabibullina, Major Research Lines in Medical-Instrument Development and Production [in Russian], Moscow (1986), pp. 155–156.

M. M. Mironov and N. V. Khabibullina, “New alloys for hardening working parts in medical instruments,” Scientific Papers from the Medical Instrumentation Research Institute (VNIIMP), New Medical Instruments [in Russian], Moscow (1984), pp. 25–26.

N. V. Khabibullina et al., Electrospark Alloying for Medical Instruments Such as Needle Holders Based on Nickel Alloys [in Russian], TsBNTImedprom, Moscow (1983).

Additional information

Scientific-Industrial Association “Medinstrument,” Kazan. Translated from Meditsinskaya Tekhnika, No. 2, pp. 21–24, March–April, 1988.

Rights and permissions

About this article

Cite this article

Maksimov, V.K., Marchenko, L.F. Electrospark alloying and wear resistance in microsurgery instruments. Biomed Eng 22, 44–46 (1988). https://doi.org/10.1007/BF00556150

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00556150