Abstract

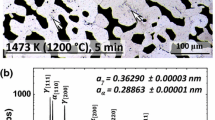

The stress corrosion cracking behaviour of the duplex Fe-10 Al-29 Mn-0.4 C alloy having two phases (α andγ) in an aqueous 20% NaCl solution (100° C) has been investigated using both the static constant load and dynamic slow strain rate tests. The constant load test shows that the duplex alloy investigated is immune to stress corrosion cracking in a 20% NaCl solution. However, the slow strain-rate test reveals that this alloy is susceptible to stress corrosion cracking at the stabilized corrosion potential, and also at potentials anodic and cathodic to this potential. Furthermore, the metallographic cross section of this duplex alloy after slow strainrate testing shows that the secondary cracks propagate transgranularly through the ferrite grains at and above the stabilized corrosion potential. However, the cracks propagate transgranularly in both the ferrite and austenite grains and also at the austenite-ferrite grain boundaries when the applied potential is cathodic to the stabilized corrosion potential.

Similar content being viewed by others

References

D. J. Schmatz,Trans. ASM 52 (1960) 898.

J. L. Ham andR. E. Cairns Jr,Prod. Eng. 29 (1958) 50.

J. Charles, A. Berghezan, A. Lutts andP. L. Dancoisne,Metal Prog. 116 (1981) 71.

J. C. Garcis, N. Rosas andK. Rioja,ibid. 117 (1982) 47.

P. Tomaszewicz andG. R. Wallwork,Corrosion 40 (1984) 152.

D. J. Schmatz,Trans. Met. Soc. AIME 215 (1959) 112.

V. G. Rivlin,Int. Met. Rev. 28 (1983) 309.

G. L. Kayak,Met. Sci. Heat Treat. 2 (1969) 95.

R. A. Lula (ed.), “Duplex Stainless Steel” (American Society for Metals, Ohio, 1982) p. 267.

R. W. Staehle, J. J. Royeula, R. L. Raredon, E. Serrate, C. R. Morin andR. V. Farrar,Corrosion 26 (1970) 451.

S. Barnatt andD. Van Rooyen,J. Electrochem. Soc. 108 (1961) 222.

H. H. Uhlig andE. W. Cook,ibid. 116 (1969) 173.

M. G. Fontana, F. H. Beck, J. W. Flowers,Met. Prog. 96 (1961) 99.

J. Hochmann, A. Desestret, R. Jolly andR. Mayond, in Proceedings of the International Conference on Stress Corrosion Cracking and Hydrogen Embrittlement of Iron Base Alloys, Unieux-Firminy, France, June 1973 (National Association of Corrosion Engineers, 1977) p. 956.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tjong, S.C. Stress corrosion cracking behaviour of the duplex Fe-10Al-29Mn-0.4C alloy in 20% NaCl solution at 100° C. J Mater Sci 21, 1166–1170 (1986). https://doi.org/10.1007/BF00553248

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00553248