Abstract

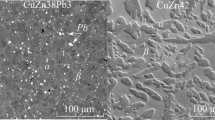

The effect of cutting speed, tool rake angle, and wearland length on the nature of the surface generated in machining annealed red brass under unlubricated and lubricated conditions is studied. The machined surfaces are examined using optical and scanning electron microscopy. The machined surfaces were observed to have defects such as microcracks and macrocracks perpendicular to the direction of relative work-tool motion, cavities and plastically deformed regions. The surface damage decreases with an increase in the cutting speed and/or the positive tool rake angle. The presence of lubricant in the cutting region results in a surface of high quality.

Similar content being viewed by others

References

S. Jeelani, PhD thesis, North Carolina State University (1975).

J. A. Bailey andS. Jeelani,Soc. Manufact. Eng. Trans. (1974) 174.

Idem, Wear 36 (1976).

J. A. Bailey, S. Jeelani andS. E. Becker,ASME, J. Eng. Ind. 98 (1976) 999.

J. A. Bailey andS. Jeelani,Wear 72 (1981) 237.

S. Jeelani andK. Ramakrishnan,ibid. 81 (1982) 263.

Idem, ibid. 82 (1982) 67.

Idem, ibid. 85 (1983) 121.

J. A. Bailey,ibid. 42 (1977) 297.

Idem, ibid. 44 (1977) 371.

P. G. Fluck,Proc. Amer. Soc. Testing and Mater. 51 (1951) 584.

W. P. Koster, L. J. Fritz andJ. B. Kohls, “Surface integrity in machining of AISI 4340 steel and Ti-6Al-4B alloy”, SME Technical Paper No. IQ71-237 (1971).

W. P. Koster andL. J. Fritz, “Surface integrity in conventional machining”, ASME Paper No. 70-GT 100 (1970).

“Machining Data Handbook” (Metcut Research Associates, Cincinnati, Ohio, 1966).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jeelani, S., Ramakrishnan, K. Surface damage in machining red brass. J Mater Sci 20, 3011–3017 (1985). https://doi.org/10.1007/BF00553067

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00553067