Abstract

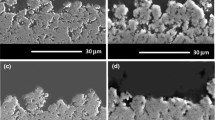

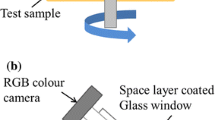

The friction and wear behaviour of binary and ternary zirconia ceramics was studied in an unlubricated environment over a range of loads and sliding speeds. In these tests, ternary zirconia ceramics based on the ZrO2-CeO2-Y2O3 system were seen to show very low friction coefficients and wear rates compared with the other binary zirconia systems investigated, with a coefficient of friction typically about 50% that of other (binary) zirconia ceramics, and a wear rate of about 1% of that of tetragonal yttria-doped zirconia. During slide testing of zirconias a transition from a low wear regime to a high wear regime was observed with increasing sliding velocity and load. SEM was used to identify the wear mechanisms.

Similar content being viewed by others

References

N. Claussen, M. Ruhle and A. H. Heuer (eds), “Advances in Ceramics”. Vol. 12, “Science and Technology of Zirconia II” (American Ceramic Society, OH, 1984).

N. Yamamoto and H. Yanagida (eds), “Advances in Ceramics”, Vol 24, “Science and Technology of Zirconia III” (American Ceramic Society, OH 1988).

F. F. Lange, G. L. Dunlop and B. I. Davis, J. Amer. Ceram. Soc. 69 (1986) 237.

T. Sato and M. Shimada, ibid. 68 (1985) 356.

C. A. Leach and N. Khan, J. Mater. Sci. 26 (1991) 2026.

D. H. Buckley and K. Miyoshi, Wear 100 (1984) 333.

R. H. J. Hannink and M. J. Murray, ibid. 100 (1984) 355.

S. Sasaki, ibid. 134 (1989) 185.

D. C. Cranmer, Tribol. Trans. 31 (1987) 164.

K. Kato, Wear (1990) 117.

R. H. Dauskardt, W. Yu and R. O. Ritchie, J. Amer. Ceram. Soc. 69 (1986) 203.

M. G. Gee, Brit. Ceram. Proc. 40 (1987) 141.

S. M. Hsu, Y. S. Wang and R. G. Munro, Wear 134 (1989) 1.

J. F. Braza, H. S. Cheng and M. E. Fine, Tribol. Trans. 32 (1989) 1.

T. E. Fischer and M. P. Anderson, J. Amer. Ceram. Soc. 72 (1989) 252.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, Y.S., Leach, C.A. Friction and wear characteristics of binary and ternary zirconia ceramics. J Mater Sci 27, 5441–5444 (1992). https://doi.org/10.1007/BF00541603

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00541603