Summary

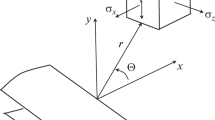

An attempt is made to modify the plasticity theory for compressible materials and then to derive the upper bound theorem or the second extremum principle which incorporate normal velocity discontinuity; this discontinuity is considered to be a measure of fracture. The theorem is applied to predict the occurrence of fracture, central bursting in extrusion or drawing. The occurrence of fracture appears to depend on the value of the parameters in the theorem; these parameters may be related to ductility or workability of the material in question. The upper bound technique is then applied to multi-stage extrusion of a carbon steel for which the values of the parameters are given with some assumptions. It is thus shown that the stage at which central bursting occurs agrees with experimental results and that it apparently depends on the extrusion condition.

Übersicht

Es wird der Versuch unternommen, mit einer modifizierten Plastizitätstheorie für kompressible Werkstoffe den Obere-Schrankensatz bzw. das zweite Extremum-Prinzip herzuleiten, wenn die Normalgeschwindigkeit auf Sprungflächen unstetig ist. Diese Unstetigkeit wird als Indikator von Bruchvorgängen angesehen. Angewandt wird diese Hypothese auf die Vorhersage des Bruchs, d. h. der Materialtrennung im Kern beim Durchdrück- bzw. Durchziehverfahren. Das Auftreten von Brüchen erweist sich als abhängig von den Parametern des Ansatzes. Diese Parameter lassen sich mit der Umformbarkeit des Materials in Zusammenhang bringen. Angewandt wird das Obere-Schranken-Konzept auf das mehrstufige Durchpressen eines Kohlenstoff-Stahls, für den die Parameterwerte mit Hilfe einiger Parameterwerte festgelegt werden. Davon ausgehend wird gezeigt, daß die Preßstufe bei Materialtrennung mit experimentellen Ergebnissen übereinstimmt und offensichtlich von den Durchpreßbedingungen abhängt.

Similar content being viewed by others

References

Oyane, M.: Criteria for ductile fracture. Bull. JSME 13 (1972) 265–270

Osakada, K.; Watadani, A.; Sekiguchi, H.: Ductile fracture of carbon steel under cold metal forming conditions. Bull. JSME 20 (1977) 1557–1562

Oyane, M.; Shima, S.; Kono, Y.: Theory of plasticity for porous metals. Bull. JSME 16 (1972) 1254 to 1262

Shima, S.; Oyane, M.: Plasticity theory for porous metals. Int. J. Mech. Sci. 18 (1976) 285–291

Gurson, A. L.: Continuum theory of ductile rupture by void nucleation and growth: part 1 — yield criteria and flow rules for porous ductile media. Trans. ASME J. Eng. Mater. Technol. 99 (1977) 2–15

Aravas, N.: The analysis of void growth that leads to central bursts during extrusion. J. Mech. Phys. Solids 34 (1986) 55–79

Gelin, J. C.: Numerical analysis of strain rate and temperature effects on localization of plastic flow and ductile fracture — applications to metal forming processes. In: Predeleanu, M. (ed.) Computational methods for predicting material processing defects, pp. 123–132. Amsterdam, Oxford, New York, Tokyo: Elsevier 1987.

Mathur, K. K.; Dawson, P. R.: Damage evolution modeling in bulk forming processes. In: Predeleann, M. (ed.) Computational methods for predicting material processing defects, pp. 251–262. Amsterdam, Oxford, New York, Toky: Elsevier 1987

Yamamoto, H.: Conditions for shear localization in the ductile fracture of void-containing materials. Int. J. Fract. 14 (1978) 347–365

Tvergaard, V.: Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 17 (1981) 389–407

Pan, J.; Saje, M.; Needleman, A.: Localization of deformation in rate sensitive porous plastic solids. Int. J. Fract. 21 (1983) 261–278

Mear, M. E.; Hutchinson, J. W.: Effect of yield surface curvature on flow localization in dilatant plasticity. Mech. Mater. 4 (1985) 395–407

Tvergaard, V.: Effect of yield surface curvature and void nucleation on plastic flow localization. J. Mech. Phys. Solids 35 (1987) 43–60

Hill, R.: The mathematical theory of plasticity. Oxford: Clarendon Press 1956

Avitzur, B.: Analysis of central bursting defects in extrusion and wire drawing. Trans. ASME J. Eng. Ind. 90 (1968) 79–91

Avitzur, B.; Choi, J. C.: Analysis of central bursting defects in plane strain drawing and extrusion. Trans. ASME J. Eng. Ind. 108 (1986) 317–321

Lippmann, H.: Mechanik des Plastischen Fließens. Berlin, Heidelberg, New York: Springer 1981

Drucker, D. C.; Prager, W.: Soil mechanics and plastic analysis of limit design. Quart. Appl. Math. 10 (1952) 157–165

Shima, S.; Tabata, T.; Oyane, M.; Kawakami, T.: Upper bound theory for deformation of porous materials. Mem. Faculty Eng., Kyoto Univ. 38 (1976) 117–137

Miki, T.: Optimization of cold forging condition considering deformation characteristics of workpiece (in Japanese). Doctoral thesis, Faculty of Engineering, Kyoto Univ. 1987

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shima, S., Nose, Y. Development of upper bound technique for analysis of fracture in metal forming. Ing. arch 60, 311–322 (1990). https://doi.org/10.1007/BF00538832

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00538832