Abstract

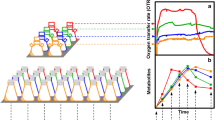

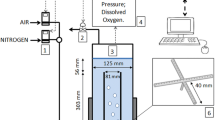

Stirred tank (STR), bubble column (BCR) and airlift (ALR) bioreactors of 0.05 and 1.5 m3 total volume were compared for the production of 2,3-butanediol using Enterobacter aerogenes under microaerobic conditions. Batch fermentations were carried out at constant oxygen transfer rate (OTR=35 mmol/lh). At 0.05 m3 scale, the STR reactor achieved much higher biomass and product concentrations than the BCR and ALR reactors. At 1.5 m3 scale, however, exactly the same biomass and product concentrations could be obtained in both STR and ALR reactors. The 1.5 m3 ALR reactor performed also much better than its counterpart at small scale, achieving a productivity 2.4-fold as high as that of the 0.05 m3 BCL and ALR reactors. No differences in performances were observed between BCR and ALR. As compared to STR the tower reactors have a 12 time higher energetic efficiency (referred to product formation) and thus should be the choice for large scale production of 2,3-butanediol.

The criterion of constant OTR or constant k L a is not applicable for the scale-up of this oxygen-sensitive culture due to strong influence of reactor hydrodynamics under microaerobic conditions. The effects of mixing and circulation time on growth and metabolism of E. aerogenes were quantitatively studied in scaled-down experiments with continuous culture. For a successful scale-up of this microaerobic culture it is necessary to have an homogeneous oxygen supply over the entire reactor volume. Under conditions of inhomogeneous oxygen supply an optimum liquid circulation time exists which gives a maximum production of 2,3-butanediol.

Similar content being viewed by others

Abbreviations

- BD:

-

2,3-butanediol

- \(C_{O_2 }^* \) [mmol/l]:

-

saturation value of dissolved oxygen

- D [h−1]:

-

dilution rate

- D [mm]:

-

reactor diameter

- D K [mm]:

-

top section diameter

- D R [mm]:

-

stirrer diameter

- D S [mm]:

-

draft tube diameter

- EtOH:

-

ethanol

- E P [kg/kWh]:

-

energy efficiency refered to product formation

- H [mm]:

-

height of reactor

- HAc:

-

acetate

- H L [mm]:

-

height of liquid

- k L a [h−1]:

-

volumetric oxygen transfer coefficient

- N [rpm=min−1]:

-

stirrer speed

- OTR [mmol/lh]:

-

oxygen transfer rate

- OUR [mmol/lh]:

-

oxygen uptake rate

- p [Pa]:

-

pressure

- P [kW]:

-

power input

- P/V L [kW/m3]:

-

specific power input

- \(P_{O_2 } \) [mmHg]:

-

oxygen partial pressure (mmHg) or

- [mmol/l]:

-

dissolved oxygen (mmol/l)

- \(q_{O_2 } \) [mmol/gh]:

-

specific oxygen uptake rate

- q P [mmol/gh]:

-

specific productivity

- R [Nm/kgK]:

-

gas constant, R = 287.06

- RQ:

-

respiration quotient

- t c [s]:

-

liquid circulation time

- T [°C or K]:

-

temperature

- TCA:

-

tricarboxylic acid

- u G [cm/s]:

-

mean superficial gas velocity

- v G [m/s]:

-

gas velocity at nozzels of gas distributor

- VG [l/h]:

-

aeration rate at inlet

- V [m3 or l]:

-

total volume

- V L [m3 or l]:

-

liquid volume

- V N [l/mol]:

-

gas mole volume under normal conditions, V N = 24.4116

- X [g/l]:

-

biomass concentration

- \(X_{CO_2 } \) :

-

CO2 mole fraction in the effluent gas

- \(X_{O_2 } \) :

-

O2 mole fraction in the effluent gas

- α :

-

inlet (above the gas distributor)

- β :

-

ratio of oxygen consumed through TCA cycle to the total oxygen uptake rate

- ρ [g/l or kg/m3]:

-

density

- Θ [%]:

-

degree homogeneity

- ω :

-

outlet of fermenter or top of the dispersion phase

References

Schügerl, K.: Bioreaction engineering, Vol 2. Chichester: Wiley, 1991

Schügerl, K.: Comparison of different bioreactor performances. Bioprocess Eng. 9 (1993) 215–223

Deckwer, W.-D.: Bubble column reactors. Chichester: Wiley, 1992

Chisti, M. Y.: Airlift bioreactors. London: Elsevier Applied Science, 1989

Reisman, H. R.: Problems in scale-up of biotechnology production processes. Crit. Rev. Biotechnol. 13 (1993) 195–253

Singh, V.; Fuchs, R.; Hensler, W.; Constantinides, A.: Scale-up and optimization of oxygen transfer in fermenters: Newtonian and non-Newtonian systems. Ann. N.Y. Acad. Sci. 589 (1990) 616

Hubbard, D.: Scaleup strategies for bioreactors containing non-Newtonian broths. Ann. N.Y. Acad. Sci. 506 (1987) 600

Trilli, A.: Scale-up of fermentation. In: Demain, A. L.; Solomon, N. A. (Eds.): Manual of industrial microbiology and biotechnology, pp. 277–307. Washington, DC: Amercian Society for Microbiology, 1986

Ju, L.-K., Chase, G. G.: Improved scale-up strategies of bioreactors. Bioprocess Eng. 8 (1992) 49–53

Yonsel, S.; Deckwer, W.-D.: Maßstabvergrößerung pneumatisch betriebener Reaktoren (Airlift/Blasensäule) für O2-limitierte Fermentationen. Bioeng. 6 (1990) 12–23

Griot, M.; Saner, U.; Heinzle, E.; Dunn, I. J.; Bourne, J. R.: Fermenter scale-up using an oxygen sensitive culture. Chem. Eng. Sci. 43 (1988) 1903–1908

Bourne, J. R.; Zurita, E. P.; Heinzle, E.: Bioreactor scale-up for the oxygen-sensitive culture Bacillus subtilis: The influence of stirrer shaft geometry. Biotechnol. Prog. 8 (1992) 580–582

Sakato, K.; Tanaka, H.; Shibata, S.; Kuratsu, Y.: Agitation-aeration studies on coenzyme Q 10 production using Rhodopseudomonas spheroides. Biotechnol. Appl. Biochem. 16 (1992) 19–28

Zeng, A.-P.; Biebl, H.; Deckwer, W.-D.: 2,3-Butanediol production by Enterobacter aerogenes in continuous culture: role of oxygen supply. Appl. Microbiol. Biotechnol. 33 (1990a) 264–268

Zeng, A.-P.; Deckwer, W.-D.: A model for multiproduct-inhibited growth of Enterobacter aerogenes in 2,3-butanediol fermentation. Appl. Microbiol. Biotechnol. 35 (1990b) 1–3

Zeng, A.-P.; Biebl, H.; Deckwer, W.-D.: Effect of pH and acetic acid on growth and 2,3-butanediol production of Enterobacter aerogenes in continuous culture. Appl. Microbiol. Biotechnol. 33 (1990c) 485–489

Zeng, A.-P.; Deckwer, W.-D.: Utilization of the tricarboxylic acid cycle, a reactor design criterion for the microaerobic production of 2,3-butanediol. Biotechnol. Bioeng. 40 (1992) 1078–1084

Yonsel, S.: Entwicklung und Erprobung eines Turm-Bioreactors im Pilotmaßstab. Ph.D. Dissertation, Technische Universität Braunschweig, Germany, 1991

Schlüter, V.: Charakterisierung und Maßstabübertragung von Biorührreaktoren, Ph.D. dissertation, Technische Universität Clausthal, Germany 1992

Zeng, A.-P.; Byun, T.-G.; Posten, C.; Deckwer, W.-D.: Use of the respiratory quotient as a control parameter for optimum oxygen supply and scale-up of microaerobic production of 2,3-butanediol. Biotechnol. Bioeng. 1994 (in print)

Harder, A.; Roels, J. A.: Application of simple structured models in bioengineering. Adv. Biochem. Eng. 21 (1982) 56–107

Einsele, A.; Ristroph, D. L.; Humphrey, A. E.: Mixing times and glucose uptake measured with a fluorometer. Biotechnol. Bioeng. 20 (1978) 1487–1492

Larson, G.; Enfors, S.-O.: Kinetics of Escherichia coli hydrogen production during short term repeated aerobic-anaerobic fluctuations. Bioprocess Eng. 9 (1993) 167–172

Amanullah, A.; Baba, A.; McFarlane, C. M.; Emery, A. N.; Nienow, A. W.: Biological models of mixing performance in bioreactors. In: Nienow, A. W. (Ed.): Bioreactor and bioprocess fluid dynamics, pp. 381–400. London: Mechanical Engineering Publications Ltd, 1993

Deckwer, W.-D.: Bioreaktoren-derzaeitiger Stand und erkennbare Entwicklung. Chem. -Ing. -Tech. 60 (1988) 583–590

Author information

Authors and Affiliations

Additional information

Dedicated to the 65th birthday of Professor Fritz Wagner.

We thank Dr. C. Posten and T. Gabel for support with the computer control system UBICON. T.-G. Byun gratefully acknowledges financial support by DAAD.

Rights and permissions

About this article

Cite this article

Byun, T.G., Zeng, A.P. & Deckwer, W.D. Reactor comparison and scale-up for the microaerobic production of 2,3-butanediol by Enterobacter aerogenes at constant oxygen transfer rate. Bioprocess Engineering 11, 167–175 (1994). https://doi.org/10.1007/BF00518739

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00518739