Summary

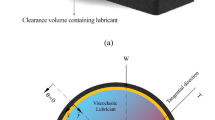

The problem of a journal bearing lubricated by a Bingham material has been solved. It has been found that the load capacity, and the moment of friction of the bearing are larger than in a journal bearing, lubricated with a Newtonian material.

Similar content being viewed by others

Abbreviations

- r :

-

radius of the journal

- c :

-

radial clearance

- r + c :

-

radius of the bearing

- e :

-

eccentricity

- w :

-

angular velocity of the journal

- h :

-

thickness of the lubricant film at any point

- δ :

-

thickness of the core

- ø :

-

angular distance of a point, from the point, where film thickness is maximum

- ε :

-

eccentricity ratio (e/c)

- x :

-

distance along the bearing surface

- y :

-

distance normal to the bearing surface

- T :

-

shear stress in the lubricant

- T 0 :

-

yield value of a Bingham solid

- μ :

-

viscosity of a Newtonian fluid

- η :

-

plastic viscosity of a Bingham solid

- p :

-

fluid pressure in the lubricant film

- Q :

-

volume flow of the lubricant

- W 0 :

-

load capacity of the bearing for ordinary lubricants

- W :

-

load capacity of the bearing

- M :

-

moment of friction

- F :

-

coefficient of friction

- δ 1 :

-

maximum thickness of the inlet core

- δ 2 :

-

maximum thickness of the outlet core

- φ 1 :

-

circumferential extent of the inlet core in the journal bearing

- φ 2 :

-

circumferential extent of the outlet core in the journal bearing

- h 0 :

-

minimum hieght of core formation in the slider bearing

- h p :

-

maximum height of core formation in the slider bearing

- u :

-

velocity of the fluid in the direction of x in the slider bearing

- V :

-

velocity in the y direction

- h 1 :

-

height of the inlet core at the circumferential extent φ 1

- h 2 :

-

height of the outlet core at the circumferential extent φ 2

- h 3 :

-

height of the outlet core in the region φ 2⩽φ⩽π

- q :

-

Q/(cwr)

- q 0 :

-

value of q for Newtonian lubricants

- p 0 :

-

pressure at φ=0

- H :

-

h/c

- H 1 :

-

h 1/c

- H 2 :

-

h 2/c

- B :

-

T 0 C/ηwr = Bingham number

References

Cohen, G. and J. W. Oren, TRANS. ASME 71 (1949) 555.

Singleterry, C. R. and E. E. Stone, J. Colloid. Sci. 6 (1951) 171.

Hersey, M. D., Theory of Lubrication, p. 91, John Wiley and Sons, Inc., New York, 1936.

Milne, A. A., Proc. 2nd int. congr. Rheol (1954) 427.

Milne, A. A., Kolloid Z. 139 (1954) 96.

Shaw, M. C. and E. F. Macks, Analysis and Lubrication of Bearings, p. 177, McGraw-Hill, New York, 1949.

Shaw, M. C. and E. F. Macks, Analysis and Lubrication of Bearings, p. 162, McGraw-Hill, New York, 1949.

Shaw, M. C. and E. F. Macks, Analysis and Lubrication of Bearings, p. 178, McGraw-Hill, New York, 1949.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Batra, R.L. Rheodynamic lubrication of a journal bearing. Appl. sci. Res. 15, 331–344 (1966). https://doi.org/10.1007/BF00411567

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00411567