Abstract

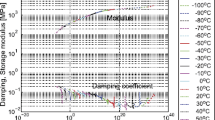

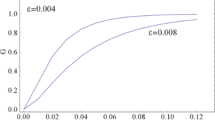

Stress relaxation tests have been carried out on a blue, pipe grade PE 80 medium density polyethylene (BP Chemicals), to provide thermo-viscoelastic rheology for use in calculating thermal stresses in pipe production. Stresses up to 4 MPa were used, with strains up to about 2%, in tests at temperatures from 23° to 90°C. Within this range a linear viscoelastic model was applicable, provided the initial ramp strain rate was less than 7×10−5 s−1. The stress relaxation data was fitted directly by a model incorporating an elastic response to volumetric strains, and a generalised linear solid model, consisting of two Maxwell elements and a purely elastic element in parallel, for deviatoric strains. Arrhenius type temperature dependence of relaxation times and shear moduli is found, and within experimental accuracy the temperature dependence of all these model parameters is the same. As a consequence, and provided that the duration of the strain ramp is sufficiently short relative to relaxation times, the model leads to time-temperature superposition of the relaxation moduli, using the same shift factor on both the response magnitude and time axes.

Similar content being viewed by others

References

Becker GW (1961) Deformationsabhängig-keit der Spannungsrelaxation von Polyäthylen verschiedenen Kristallisationsgrades. Kolloid-Zeitschrift 175:99

Catsiff E, Offenbach J, Tobolsky AV (1956) Viscoelastic properties of crystalline polymers: polyethylene. J Colloid Sci 11:48

Eder G, Janeschitz-Kriegl H, Liedauer S (1990) Crystallisation processes in quiescent and moving polymer melts under heat transfer conditions. Prog Polym Sci 15:629

Faucher JA (1959) Viscoelastic behaviour of polyethylene and polypropylene. Trans Soc Rheol, III, 81

Findley WN, Reed RM, Stern P (1967) Hydrostatic creep of solid plastics. J Appl Mech Trans ASME, 895, December

McCrum NG, Morris EL (1989) On the measurement of the activation energies for creep and relaxation. Proc Roy Soc A201:258

Nagamatsu K (1960) On the viscoelastic properties of crystalline high polymers. Kolloid-Zeitschrift 172:141

Nakayasu H, Markovitz H, Plazek DJ (1961) Dynamic properties of polyethylene. Trans Soc Rheol IV, 281

Pittman JFT, Farah IA (1995) Computer simulation of the cooling process in plastic pipe manufacture, including sag, thermal stress and morphology. Proc Plastic Pipes IX (Inst. Materials) Edinburgh, 364

Pittman JFT, Whitham GD, Beech S, Gwynn DG (1994) Cooling and wall thickness uniformity in plastic pipe manufacture. Int Polymer Processing 9:130

Popelar CF, Popelar CH, Kenner VH (1990) Viscoelastic material characterisation and modelling for polyethylene. Poly Eng and Sci 30:577

Ratajski E (1993) Kristallisationserscheinungen in ruhenden Polymerschmelzen. Disseration, Univ Linz

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pittman, J.F.T., Farah, I.A. A linear viscoelastic model for solid polyethylene. Rheol Acta 36, 462–471 (1997). https://doi.org/10.1007/BF00396331

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00396331