Abstract

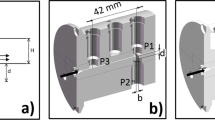

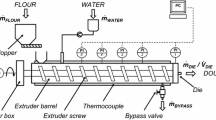

A novel in-line rheometer, called “Rheopac”, has been designed and built in order to study the rheological behaviour of starchy products or, more generally, of products sensitive to a thermomechanical treatment. It is based on the principle of a twin channel, using a balance of feed rate between each of them, in order to make local shear rate vary in the measuring section without changing the flow conditions into the extruder. A wide range of shear rate could be reached and measurements were performed more swiftly than with a classical slit die. The viscous behaviour of maize starch was studied by taking into account the influence of the thermomechanical history, which modified the starch degradation and thus led to important variations in the viscosity. Experimental results were satisfactorily compared to previously published models.

Similar content being viewed by others

Abbreviations

- E :

-

activation energy (J · mol−1)

- h :

-

channel depth (m)

- h 1 :

-

depth under the piston valve in channel 1 (m)

- h 2 :

-

depth under the piston valve in channel 2 (m)

- K :

-

consistency (Pa·sn)

- K 0 :

-

reference consistency (Pa·sn)

- L :

-

total channel length (m)

- L p :

-

length of the piston valve (m)

- MC:

-

moisture content (wet basis)

- n :

-

power law index

- N :

-

screw rotation speed (rpm)

- P 0 :

-

entrance pressure (Pa)

- P e :

-

pressure at the entry of the piston valve (Pa)

- Q 1 :

-

flow rate in channel 1 (m3 · s−1)

- Q 2 :

-

flow rate in channel 2 m3·s−1)

- Q T :

-

total flow rate (m3 · s−1)

- R :

-

constant of perfect gas (8.314 J·mol−1·K−1)

- SME:

-

specific mechanical energy (kWh · t−1)

- T :

-

temperature (°C)

- T a :

-

absolute temperature (K)

- T b :

-

barrel temperature (°C)

- T d :

-

die temperature (°C)

- T p :

-

product temperature (°C)

- w :

-

channel width (m)

- W :

-

energetical term (J·m−3)

- η :

-

viscosity (Pa · s)

- [gh 0]:

-

intrinsic viscosity of native starch (ml·g−1)

- [η]:

-

intrinsic viscosity (ml·g−1)

- \(\dot \gamma \) :

-

shear rate (s−1)

- \(\dot \gamma _1 \) :

-

shear rate in measuring section (s−1)

- \(\dot \gamma _{\max } \) :

-

maximum shear rate (s−1)

References

Agassant JF, Avenas P, Sergent JP, Carreau PJ (1991) Polymer processing, principles and modeling. Hanser Verlag Ed, Munich

Colonna P, Tayeb J, Mercier C (1989) Extrusion cooking of starch and starchy products. In: Mercier C et al. (eds) Extrusion-Cooking. Am Assoc Cereal Chem, St. Paul. Minnesota, p 247

Dealy JM, Wissbrun KF (1989) Melt theology and its role in plastics processing. Van Nostrand Reinhold Ed, New York

Della Valle G, Koszlowski G, Colonna P, Tayeb J (1989) Starch transformation estimated by the energy balance on a twin screw extruder. Lebens Wiss Technol 22:279–286

Della Valle G, Vergnes B, Tayeb J (1992a) Measurements of the viscosity of low hydrated molten starches with a new in-line rheometer. Entropie 64:59–63

Della Valle G, Vergnes B, Tayeb J, Boche Y (1992 b) A new in-line rheometer to measure the viscosity of extruded starchy products. In: Moldenaers P, Keunings R (eds) Theoretical and applied theology. Elsevier, London, pp 702–704

Laun HM (1983) Polymer melt theology with a slit die. Rheol Acta 22:171–185

Lai LS, Kokini JL (1990) The effect of extrusion operating conditions on the on-line apparent viscosity of 98%, amylopectin and 70%, amylose corn starches during extrusion. J Rheol 34:1245–1266

Mackey KL, Ofoli RY (1990) Rheological modelling of corn starch doughs at low to intermediate moisture. J Food Sci 55:417–423

Mourniac P, Agassant JF, Vergnes B (1992) Determination of the wall slip velocity in the flow of a SBR compound. Rheol Acta 31:565–574

Padmanabhan M, Bhattacharya M (1991) Flow behaviour and exit pressures of corn meal under high shear high temperature extrusion conditions using a slit die. J Rheol 35:315–343

Parker R, Ollett A-L, Lai-Fook RA, Smith AC (1990 a) The rheology of food melts and its application to extrusion processing. In: Carter RE (ed) Rheology of food, pharmaceutical and biological materials. Elsevier, London

Parker R, Ollett A-L, Smith AC (1990b) Starch melt rheology: measurements, modelling and application to extrusion processing. In: Zeuthen et al. (eds) Processing and quality of foods. Elsevier, London, vol 1, p 290–295

Senouci A, Smith AC (1988) An experimental study of food melt rheology. I: shear viscosity using a slit die viscometer and a capillary rheometer. Rheol Acta 27:546–554

Springer P, Broadkey RS, Lynn RE (1975) Development of an extrusion rheometer suitable for on-line rheological measurements. Polym Eng Sci 15:583–587

Vergnes B, Villemaire JP (1987) Rheological behaviour of low moisture molten maize starch. Rheol Acta 26:570–576

Vergnes B, Villemaire JP, Colonna P, Tayeb J (1987) Interrelationships between thermomechanical treatment and macromolecular degradation of maize starch in a novel rheometer with preshearing. J Cereal Sci 5:189–202

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vergnes, B., Della Valle, G. & Tayeb, J. A specific slit die rheometer for extruded starchy products. Design, validation and application to maize starch. Rheol Acta 32, 465–476 (1993). https://doi.org/10.1007/BF00396177

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00396177