Abstract

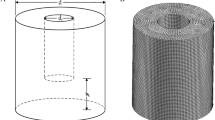

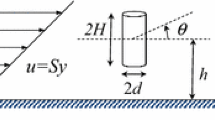

The motion and distribution of microcarriers inside a horizontally rotating cylindrical bioreactor were simulated using spherical ion exchange resin particles. Particle motion deviated much from that expected under ideal conditions. The possible mass transfer enhancing effects of particle translation and cluster rotation are discussed.

Similar content being viewed by others

Abbreviations

- C kg/m3 :

-

solute concentration

- D m2/s:

-

diffusion coefficient

- d p m:

-

microcarrier diameter

- J c kg m2/s:

-

solute flux due to cluster translation

- J p kg m2/s:

-

solute flux due to particle translation

- n l/m3 :

-

microcarrier number density

- R m:

-

bioreactor radius

- r m m:

-

mixing plane location

- r 0 m:

-

trajectory radius

- r c m:

-

cluster radius

- r cc m:

-

radial position of cluster center

- v g m/s:

-

particle settling velocity

- x l/m3 :

-

cell concentration

- X m:

-

current particle position on the rotating X axis

- Y m:

-

current particle position on the rotating y axis

- α :

-

liquid fraction actually conveyed by cluster rotation

- β :

-

total associated liquid volume/reactor volume

- γ 0 kg/(cell h):

-

specific oxygen consumption rate

- Δr m:

-

half the distance between mixing planes

- δ m:

-

cluster boundary layer thickness

- ε :

-

microcarrier volume fraction

- v m3/m2 :

-

volumetric flowrate per unit area of fluid in the rotating boundary layer

- μ ∫ Pa s:

-

liquid viscosity

- ρ kg/m3 :

-

density

- τ max Pa:

-

maximum shear stress

- ω l/min:

-

cylinder rotational speed

- A :

-

particle A

- A 0 :

-

initial position of particle A

- B :

-

particle B

- B 0 :

-

initial position of particle B

- c :

-

cluster

- cc :

-

cluster center

- eq, c :

-

equivalent, cluster

- eq, p :

-

equivalent, particle

- f :

-

fluid

- max :

-

maximum

- 0 :

-

initial

- O 2 :

-

oxygen

- p :

-

particle

- r 0 + r m :

-

average radial position

- r 0 − r m :

-

average radial position

References

Katinger, H.; Scheirer, W.: Mass cultivation and production of animal cells in: Spier, R. E.; Griffiths, J. B. (Eds.): Animal Cell Biotechnology, vol. 1, 167–193. London: Academic Press. 1985

Griffiths, B.; Looby, D.: Fixed immobilized beds for the cultivation of animal cells. In: Ho, C. S.; Wang, D. I. C. (Eds.): Animal Cell Bioreactors, 171–172. Massachusetts: Butterworth-Heinemann. 1991

Griffiths, B.: Advances in animal cell immobilization technology. In: Spier, R. E.; Griffiths, J. B. (Eds.): Animal Cell Biotechnology, vol 4, 149–166. London: Academic Press. 1990

Griffiths, B.: Scaling-up of animal cell cultures. In: Freshney, R. I. (Ed.): Animal Cell Culture: A Practical Approach 33–69. Oxford: IRL Press. 1986

van Wezel, A. L.: Growth of cell strains and primary cells on micro-carriers in homogeneous culture. Nature. 216 (1967) 64–65

Spier, R. E.; Maroudas, N.: Microcarriers for animal cell biotechnology: An unfulfilled potential. In: Ho, C. S.; Wang, D. I. C. (Eds.): Animal Cell Bioreactors, 191–212. Massachusets: Butterworth-Heinemann. 1991

Cherry, R.; Papoutsakis, E.: Hydrodynamic effects on cells in agitated tissue culture reactors. Bioproc. Eng. 1 (1986) 29–41

Kariya, M.; Tozaki, C.: A new bioreactor: Horizontally rotating culture method. Hakkou to Kougyou, 47 (1987) 206–213 (in Japanese)

Tanaka, H.; et al.: Rotating drum fermentor for plant cell suspension cultures. Biotech. Bioeng., 25 (1983) 2359–2370

Voit, H.; Gotz, F.; Mersmann, A. B.: Overproduction of lipase with Staphylococcus carnosus (pLipPS1) under modified gravity in a centrifugal field bioreactor. Chem. Eng. Technol. 12 (1989) 364–373

Weidenbaum, S.: Mixing of solids. In: Drew and Hoopes (Eds.): Advances in Chemical Engineering, vol 2, 209–321. New York: Academic Press. 1958

Perry, R. H.; Green, D. W.; Maloney, J. O.: Perry's Chemical Engineering Handbook, 6th ed., p. 19–53. New York: McGraw-Hill. 1984

Clump, C.: Mixing of Solids. In: Uhl, V. W. and Gray, J. B. (Eds.): Mixing Theory and Practice. 263–286. New York Academic Press. 1967

Shirotsuka, T. (Ed.): Dictionary of chemical engineering., p. 541. Tokyo Maruzen. 1986 (in Japanese)

Stathopoulos, N. A.; Hellums, J. D.: Shear stress effects on human embryonic kidney cells in vitro. Biotechnol. Bioeng. 27 (1985) 1021–1026

Tramper, J.; Joustra, D.; Vlak, J. M.: Bioreactor design for the growth of shear-sensitive insect cells. In Webb, C.; Mavituna, F. (Eds.): Plant and Animal Cells Process Possibilities. 125–136. England Ellis Horwood. 1987

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

delos Santos, B., Shiragami, N., Unno, H. et al. Simulated-microcarrier motion and its effect on radial medium transfer inside a horizontally rotating cylindrical bioreactor (HRCB) for animal cell culture. Bioprocess Engineering 10, 5–14 (1994). https://doi.org/10.1007/BF00373529

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00373529