Abstract

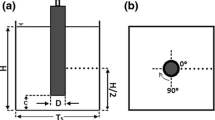

A horizontal rotating tubular bioreactor (HRTB) was designed as a combination of a “thin-layer bioreactor” and a “biodisc” reactor whose interior was divided by O-ring shaped partition walls. For the investigation of mixing in HRTB the temperature step method was applied. Temperature changes in the bioreactor were monitored by six Pt-100 sensors (t 90 response time 0.08 s and resolution 0.002 °C) which were connected with an interface unit and a personal computer. In this work a modified “tank in series” concept was used to establish a mathematical model. The heat balance of the model compartments was established according to the physical model and the “spiral flow” pattern. Numerical integration was done by the Runge-Kutta-Fehlberg method. The mathematical mixing model called “spiral flow” model contained four adjustable parameters (N1, Ni, F cr and F p) and five parameters which characterized the plant and experimental conditions. The “spiral flow” model was capable to describe the mixing in HRTB properly, and its applicability was much better than with the “simple flow” model, presented earlier.

Similar content being viewed by others

Abbreviations

- A ui m2 :

-

ithpart of inner surface of bioreactor's wall

- A vi m2 :

-

ith part of outlet surface of bioreactor's wall

- C p kJ kg–1 K–1 :

-

heat capacity of liquid

- c pr kJ kg−1 K–1 :

-

heat capacity of bioreactor's wall

- D h–1 :

-

dilution rate

- E °C°C–1h–1 :

-

error of mathematical model

- F cr dm3 s–1 :

-

circulation flow in the model

- F p dm3s–1 :

-

back flow in the model

- F t dm3 s–1 :

-

inlet flow in bioreactor

- I °C:

-

intensity of temperature step, the difference in temperature between the temperature of the inlet liquid flow and the temperature of liquid in bioreactor before temperature step

- K1 Wm–2 K –1 :

-

heat transfer coefficient between the liquid and bioreactor's wall

- K2 Wm–2 K –1 :

-

heat transfer coefficient between the bioreactor's wall and air

- L m:

-

length of bioreactor

- m s kg:

-

mass of bioreactor's wall

- n min–1 :

-

rotational speed of bioreactor

- n s :

-

number of temperature sensors

- N1:

-

number of cascades

- Ni :

-

number of compartments inside cascade

- r u m:

-

inner diameter of bioreactor

- r v m:

-

outside diameter of bioreactor

- s(t) :

-

step function

- t s:

-

time

- T °C:

-

temperature

- T c °C:

-

calculated temperature

- T m °C:

-

measured temperature

- T N 1,Ni°C:

-

temperature of liquid in defined compartments inside the cascade

- T N 1,S°C:

-

temperature of defined part of bioreactor's wall

- T N i,z°C:

-

temperature of surrounding air

- V t dm3 :

-

volume of liquid in the bioreactor

References

Šantek, B.; Horvat, P.; Novak, S.; Mayr, B.; Moser, A.; Marić, V.: Mathematical model of mixing in horizontal rotating tubular bioreactor: “Simple flow” model, Bioprocess Eng. in press

Burden, R. L.; Faires, J.D.: Error control and the Runge-Kutta-Fehlberg method. In Numerical analysis, pp. 251–255. Boston: PWS-KENT Publ. 1989

Oosterhuis, N.M.G.; Kossen, N.W.F.: Modelling and scaling-up of bioreactor. In: Ed. H. Brauer, Fundamentals of biochemical engineering, vol. 2, pp. 571–605. Weinheim: Deerfield Beach FL VCH 1985

Moser, A.; Mayr, B.; Jury, W.; Steiner, W.; Horvat, P.: Mathematical models for mixing in deep jet bioreactors: analysis. Bioprocess Eng. 7 (1991) 171–176

Moser, A.; Mayr, B.; Jury, W.; Steiner, W.; Horvat, P.: Mathematical models for mixing in deep jet bioreactors: calculation of parameters. Bioprocess Eng. 7 (1991) 177–181

Mayr, B.; Horvat, P.; Moser, A.: Engineering approach to mixing quantification in bioreactors. Bioprocess Eng. 8 (1992) 137–143

Jury, W.: Mixing in Bioreactors, Ph.D. Thesis, Institute of Biotechnology, Graz University of Technology (1989)

Mukataka, S.; Kataoka, H.; Takahashi, J.: Effects of vessel size and rheological-properties of suspensions on the distribution of circulation times in stirred vessels. J. Ferment. Technol. 58 (1980) 155–161

Danckwerts, P.V.: The effect of incomplete mixing on homogeneous reactions. Chem. Eng. Sci. 8 (1958) 93–102

Zwietering, T.N.: The degree of mixing in continuous flow systems. Chem. Eng. Sci. 11 (1959) 1–15

Mayr, B.; Nagy, E.; Horvat, P.; Moser, A.: Scale-up on basis of structured mixing models: a new concept. Biotechnol. Bioeng. 43 (1994) 195–206

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Šantek, B., Horvat, P., Novak, S. et al. Mathematical modeling of mixing in a horizontal rotating tubular bioreactor: “Spiral flow” model. Bioprocess Engineering 14, 223–229 (1996). https://doi.org/10.1007/BF00369917

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369917