Abstract

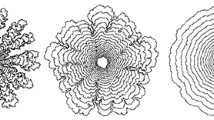

Starting from the results of a morphologically detailed description of pellet development, a mathematical model is presented which is expected to yield equivalent results with substantially less computing expenditure. The simplification of the original model (part I of the paper) resulted in an about 60–100fold reduction of the demands for computing capacity. This was achieved by averaging the mycelial morphology within radial layers. Quantities such as cell volume density and substrate consumption rates were taken to be constant within a layer. The description by means of partial differential equations was intentionally omitted except for the mass-transfer into the pellet. The results of the layer model show a far-reaching equivalence to the detailed single-hypha-model. Data from image processing investigations and microprobe measurements of oxygen and glucose in Penicillium chrysogenum pellets correspond to the simulation results. The model appears suitable for further process-simulations with larger ensemble of pellets.

Similar content being viewed by others

Abbreviations

- C i,R :

-

concentration of component i (i=O, S) (gl−1)

- C i,crit :

-

substrate concentration i critical for lysis (i = O, S)(gl−1)

- C i ,stop :

-

concentration of substance i below which cells are inactivated (gl−1)

- CPU:

-

central processing unit

- d h :

-

cross-sectional diameter of hyphae (μm)

- D eff,i :

-

effective diffusion coefficient of substance i(i= O, S) (m2 h−1)

- D i ,max :

-

maximal molecular diffusion coefficient of substance i in water at 25 °C (i = O, S) (m2 h−1)

- D tips :

-

transport coefficient of tips (m2 h−1)

- hgu⋆ :

-

standard hyphal growth unit at r = 180 μm (μm)

- hgu R :

-

local hyphal growth unit of layer R (μm)

- k i :

-

Monod coefficient for substrate i (i=O, S) (gl−1)

- L i :

-

total length of branch i (i=1, 2, 3) (μm)

- L m :

-

length of a hyphal segment, Eq. (13) (μm)

- L R :

-

total hyphal length in layer R (μm)

- l shear :

-

constant in Eq. (8)

- n R :

-

current number of growing tips in layer R

- n /⋆ g :

-

number of tips (including inactive and already lysed) in layer R

- n s :

-

number of segments (de novo part of the model)

- n shear,R :

-

number of broken tips in layer R

- O :

-

index for oxygen

- pO2 :

-

pressure of dissolved oxygen (%)

- Q i :

-

uptake rate of substrate i (i=O, S) (gl−1 −1)

- R :

-

index of radial layer (R=1, 2, 3,..., R max)

- r :

-

radius (μm)

- R max :

-

index of the outmost layer of the pellet

- r tip :

-

distance from the pellet centre to the tip position (μm)

- r thr :

-

threshold radius (μm)

- S :

-

index for glucose

- SHM:

-

single hypha model (part I of the paper)

- t :

-

time (h)

- t end :

-

time at the end of the simulation (h)

- v r :

-

volume of layer R (μm3)

- Y Mi :

-

observable yield coefficient of biomass on substrate i (gg−1)

- Y Xi :

-

yield coefficient of biomass on substrate i (gg−1

- α :

-

mean tip extension rate (μm h−1)

- α ly :

-

lysis rate (μm h−1)

- α :

-

maximal tip extension rate, single hyphae model (μm h−1)

- γ :

-

angle between segments of the main hypha

- ΔL + R :

-

increment of hyphal length due to growth/lysis (μm)

- ΔL − R :

-

increment of hyphal length due to shear breakup (μm)

- λ shear :

-

shear force parameter

- μ m :

-

maximal specific growth rate of a hypha (h−1)

- ρ s :

-

shear force parameter

- ρ x :

-

cell mass density (g dry weight per 1 wet cells)

- ϕ R (C i ):

-

normalized growth kinetics on substrate i (i=O,S)

References

Buschulte, T. K.: Mathematische Modellbildung und Simulation von Zellwachstum, Stofftransport und Stoffwechsel in Pellets aus Streptomyceten. Ph.D. thesis, Universität Stuttgart (1992)

Buschulte, T. K., Gilles, E. D.: Modeling and simulation of hyphal growth, metabolism and mass transfer in pellets of Streptomyces. Eur. Congr. Biotech. 5 (1990) 279–282

Caldwell, I. Y., Trinci A. P. J.: The growth unit of the mould Geotrichum candidum. Arch. Mikrobiol. 88 (1973) 1–10

Cronenberg, C. C. H.: Biofilms investigated with needle-type glucose sensors. Ph.D. thesis, University of Amsterdam (1994).

Cronenberg, C. C. H., Ottengraf, S. P. P., van den Heuvel, J. C., Pottel, F., Sziele, D., Schügerl, K., Bellgardt, K.-H.: Influence of age and structure of penicillium chrysogenum pellets on the internal concentration profiles. Bioproc. Eng. (1995) in press

Georgiou, G., Shuler, M. L.: A computer model for the growth and differentiation of a fungal colony on solid substrate. Biotechnol. Bioeng. 28 (1986) 405–416

Hotop, S., Möller, J., Schügerl, K.: Influence of the preculture conditions on the pellet size distribution of Penicillium chrysogenum cultivations. Process Biochem. 38 (1993) 99–104

Kobaayshi, T., van Dedem, G., Moo-Young, M.: Oxygen transfer into mycelial pellets, Biotechnol. Bioeng. 15 (1973) 27–45

Metz, B.: From pulp to pellet. An engineering study on the morphology of moulds. Ph.D. thesis, Delft (1976)

Meyerhoff, J., Tiller, V., Bellgardt, K.-H.: Two mathematical models for the development of a single microbial pellet. Part I. Detailed morphological model based on the description of individual hyphae. submitted to Bioproc. Eng. (1995) in press

Michel, F. C. Jr., Grulke, E.A., Reddy, C. A.: A kinetic model for the fungal pellet lifecycle. AIChE J. 38 (1992) 1449–1460

Ngian, K. F., Lin, S.H.: Diffusion coefficient of oxygen in microbial aggregates. Biotechnol. Bioeng. 18 (1976) 1623–1627

Pottel, F.: Untersuchungen zur Morphologie an Penicillium chrysogenum-Pellets. Ph.D. thesis in preparation, Universität Hannover, 1995

Pottel, F., Bellgardt, K.-H.: Investigation of morphology of pellets during cultivations of Penicillium chrysogenum by digital image processing. DECHEMA Biotechnol. Conf., 5, PtA (1992) 381–386

van Suijdam, J. C.: Mycelial pellet supensions, biotechnology aspects, Ph.D. thesis, Delft (1980)

Tanford, C.: Physical Chemistry of Macromolecules, p. 156. NewYork: John Wiley and Sons 1961.

Tiller, V., Meyerhoff, J., Sziele, D., Schügerl, K., Bellgardt, K.-H.: Segregated mathematical model for the fed-batch cultivation of a high-producing strain of Penicillium chrysogenum. J. Biotechnol. 34 (1994) 113–131

Villadsen, J. V., Stewart, W. E.: Solution of boundary-value problems by orthogonal collocation. Chem. Eng. Sci. 22 (1967) 1483–1501

Viniegra-González, G., Saucedo-Castañeda, G.: Symmetric branching model for the kinetics of mycelial growth. Biotechnol. Bioeng. 42 (1993) 1–10

Wittler, R., Baumgartl, H., Lübbers, D. W., Schügerl, K.: Investigations of oxygen transfer into Penicilium chrysogenum pellets by microprobe measurements, Biotechnol. Bioeng. 28 (1986) 1024–1036

Yang, H., Reichl, U., King, R., Gilles, E.D.: Measurement and simulation of the morphological development of filamentous microorganisms. Biotechnol. Bioeng. 39 (1992) 44–48

Yang, H., King, R., Reichl, U., Gilles, E. D.: Mathematical model for apical growth, septation and branching of mycelial microorganisms. Biotech. Bioeng. 39 (1992) 49–58

Yano, T., Kodama, T., Yamada, K.: Fundamental studies of the aerobic fermentation. Agric. Biol. Chem. 25 (1961) 580–584

Meyerhoff, J., Bellgardt, K.-H.: A morphology-based model for fed-batch cultivations of Penicillium chrysogenum growing in pellet form. J. Biotechnol. (1995) in print

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Meyerhoff, J., Bellgardt, K.H. Two mathematical models for the development of a single microbial pellet. Bioprocess Engineering 12, 315–322 (1995). https://doi.org/10.1007/BF00369508

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369508