Abstract

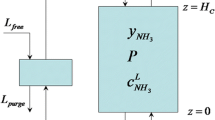

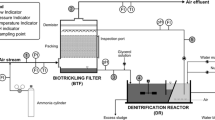

The removal of dichloromethane from waste gases in a biological trickling filter was studied experimentally as well as theoretically within the concentration range of 0–10,000 ppm. A stable dichloromethane elimination performance was achieved during two years of operation, while the start-up of the system only amounted to several weeks at constant inlet concentrations. The trickling filter system was operated co-currently as well as counter-currently.

However, experimental and theoretical results revealed that the relative flow direction of the mobile phases did not significantly affect the elimination performance. Moreover, it was found that the gas-liquid mass-transfer resistance in the trickling filter bed applied was negligible, which leaves the biological process inside the biofilm to be the rate limiting step.

A simplified model was developed, the “Uniform-Concentration-Model”, which showed to predict the filter performance close to the numerical solutions of the model equations. This model gives an analytical expression for the degree of conversion and can thus be easily applied in practice.

The dichloromethane eliminating performance of the trickling filter described in this paper, is reflected by a maximum dichloromethane elimination capacity EC max=157 g/(m3 · h) and a critical liquid concentration C lcr=45 g/m3 at a superficial liquid velocity of 3.6 m/h, inpendent of the gas velocity and temperature.

Similar content being viewed by others

Abbreviations

- a s m2/m3 :

-

specific area

- a w m2/m3 :

-

specific wetted area

- A m2 :

-

cross-sectional area

- C g g/m3 :

-

gas phase concentration

- C go g/m3 :

-

inlet gas phase concentration

- C gocr g/m3 :

-

critical gas phase concentration

- C * g :

-

Cg/Cgo dimensionless gas concentration

- C l g/m3 :

-

liquid concentration

- C lcr g/m3 :

-

critical liquid concentration

- C * lcr :

-

mClcr/Cgo dimensionless critical concentration

- c li g/m3 :

-

substrate concentration at liquid-biofilm interface

- C * l :

-

mCl/Cgo dimensionless liquid concentration

- C o g/m3 :

-

oxygen concentration inside the biofilm

- C oi g/m3 :

-

oxygen concentration at liquid-biofilm interface

- Cs g/m3 :

-

substrate concentration inside the biofilm

- C si g/m3 :

-

substrate concentration at liquid-biofilm interface

- D eff m2/h:

-

effective diffusion coefficient in the biofilm

- D o m2/h:

-

effective diffusion coefficient for oxygen in the biolayer

- E :

-

mug/ul extraction factor

- E act kJ/mol:

-

activation energy for the biological reaction

- EC g/(m3· h):

-

K o a w δ η: elimination capacity, or the amount of substrate degraded per unit of reactor volume and time

- EC max g/(m3 · h):

-

K o awδ: maximum elimination capacity

- f :

-

degree of conversion

- h m:

-

coordinate in height

- H m:

-

height of the packed bed

- K 0 g/(m3 · h):

-

μmaxXb/Y zeroth order reaction defined per unit of biofilm volume

- k og m/h:

-

overall gas phase mass transfer coefficient

- K * :

-

dimensionless constant given by Eq. (A.5)

- K * l :

-

dimensionless constant given by Eq. (A.6)

- K *2 :

-

dimensionless constant given by Eq. (A.6)

- m :

-

C g /Cl gas liquid distribution coefficient

- N g/(m2 · h):

-

liquid-biofilm interfacial flux of substrate

- N og :

-

kogawH/ug number of gas phase transfer units

- N r :

-

ko aw δ H/ug Cgo number of reaction units

- OL g/(m3· h):

-

u g C go /H organic load

- r s g/(m3 ·h):

-

zeroth order substrate degradation rate given by Eq. (1)

- R s g/(g TSS ·h):

-

specific activity

- T K:

-

absolute temperature

- u g m/h:

-

superficial gas velocity

- u t m/h:

-

superficial liquid velocity

- X b g TSS/m3 :

-

biomass concentration inside biofilm

- X s g TSS/m3 :

-

liquid suspended biomass concentration

- x m:

-

coordinate inside the biofilm

- Y g TSS/(gDCM):

-

yield coefficient

- Г :

-

dimensionless parameter given by Eq. (2)

- δ m:

-

averaged biofilm thickness

- η :

-

biofilm effectiveness factor given by Eqs. (7a)–(7c)

- Λ m:

-

penetration depth of substrate into the biofilm

- μ max d−1 :

-

microbiological maximum growth rate

- v o :

-

stoichiometric utilization coefficient for oxygen

- v s :

-

stoichiometric utilization coefficient for substrate

- ξ :

-

dimensionless height in the filter bed

- τ h:

-

H/u g superficial gas phase contact time

- Φ o :

-

Λ(K 0 /DC ii )1/2

- ψ o :

-

C o /C oi dimensionless oxygen concentration inside the biofilm

- ψ s :

-

C s /C si dimensionless substrate concentration inside the biofilm

Author information

Authors and Affiliations

Additional information

Experimental results, verifying the model presented will be discussed Part II (to be published in Vol. 6, No. 4)

Rights and permissions

About this article

Cite this article

Diks, R.M.M., Ottengraf, S.P.P. Verification studies of a simplified model for the removal of dichloromethane from waste gases using a biological trickling filter. Bioprocess Engineering 6, 93–99 (1991). https://doi.org/10.1007/BF00369061

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00369061