Abstract

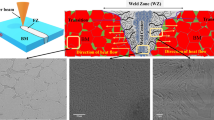

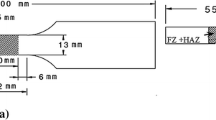

The microstructural development of the Al-Li-Cu-Mg-Zr alloy 8090 has been studied after autogenous CO2 laser welding. Sheets ranging in thickness from 1–4 mm were welded at speeds of between 20–120 mm s−1 and powers from 1.5–3.8 kW. Optical microscopy, scanning and transmission electron microscopy were used to study the as-received base metal, the heat-affected zone and the solidified fusion zone. The base metal was supplied in a superplastically formable condition and thus had an unrecrystallized grain structure containing 1–2 μm sized sub-grains with sub-micrometre δ′ and β′ precipitates in the matrix. In the fusion zone, the as-solidified grain structure was columnar at the interface with the base metal but became equiaxed in the central region of the weld pool. The weld depth and top bead width both increased with decreasing welding speed and increasing beam power within the limits investigated. The fusion zone microstructure was cellular-dendritic. Intermetallic precipitates, which are rich in copper, magnesium, silicon (and presumably lithium), formed in the cell/dendrite boundaries. Very fine-scale δ′ precipitates were present in the as-solidified α-Al matrix but there was no evidence for the β′, S′ and T1 phases. The heat-affected zone was only 100 μm wide and was characterized by regions of partial melting. Radiographs of welds reveal that porosity occurred predominantly along the weld centre-line. In partial penetration welds, two types of pores were observed: near spherical and irregular. However, in fully penetrating welds, only the spherical type of porosity was present. Overall volume fractions of porosity were measured from metallographic sections and were found to vary with welding speed and weld type, i.e. partial or full penetration.

Similar content being viewed by others

References

R. GRIMES, A. J. CORNISH, W. S. MILLER and M. A. REYNOLDS, Met. Mater. 1 (1985) 357.

P. E. BRETZ and R. G. GILLILAND, Light Met. Age 45 (3–4) (1987), 7.

A. J. CORNISH, A. GRAY, W. S. MILLER and M. A. REYNOLDS, in “Proceedings of the 3rd European Symposium on Spacecraft Materials in Space Environment”, Noordwijk, Netherlands, 1985, pp. 195–201.

J. R. PICKENS, J. Mater. Sci. 25 (1990) 3035.

R. GRIMES, W. S. MILLER and R. G. BUTLER, J. Phys.(France) 48 (1987) C3–239.

I. J. POLMEAR, “Light Metals” (Edward Arnold, London, 1981) p. 94.

P. A. MOLIAN and T.S. SRIVATSAN, J. Mater. Sci. 25 (1990) 3347.

D. S. GNANAMUTHU and R. J. MOORES, in E. A. METZBOWER and D. HAUSER (eds), “Power Beam Processing”, (ASM, Metals Park, Ohio, 1989) pp. 181–3.

A. J. SUNWOO and J. W. MORRIS, Metall. Trans. 22A (1991) 903.

Idem, Weld. J. 69 (1989) 262-S.

B. BIERMANN, R. DIERKEN, R. KUPFER, A. LANG and H. W. BERGMANN, in “Proceedings of the 6th International Al-Li Conference”, October 1991, Garmisch, Germany, to be published.

W. E. QUIST and G. H. NARAYANAN, in “Modern Aluminium Alloys”, edited by A. K. VASUDEVAN and R. D. DOHERTY (Academic Press, New York, 1989) p. 219.

P. J. GREGSON and H. M. FLOWER, Mater. Sci. Technol. 3 (1987) 81.

J. M. SILCOCK, J. Inst. Met. 88 (1959–1960) 357.

F. W. GAYLE and J. B. VANDERSANDE, Scripta Metall. 19 (1984) 473.

N. RYUM, Acta Metall. 17 (1969) 269.

O. IZUM, ibid. 17 (1969) 619.

R. N. WILSON and P. G. PARTRIDGE, ibid. 13 (1965) 1321.

W. A. CASSADA, G. J. SHIFLET and E. A. STARKE, Metall. Trans. 22A (1991), 287.

“Metals Handbook”, 9th Edn, Vol. 9 (ASM International, Metals Park OH, 1988) pp. 351–88.

W. M. STEEN, “Laser Material Processing” (Springer-Verlag, London, 1991) pp. 108–44.

G. J. DAVIES, “Solidification and Casting” (Applied Science, London, 1973) pp. 55–67.

W. S. MILLER and J. WHITE, in “Superplasticity in Aerospace” (TMS, Warrendale, PA, 1988) pp. 211–28.

D. H. SHIN, Y. H. SHIN, Y. W. CHANG and S. C. MAENG, Scripta Metall. Mater. 26 (1992) 117.

J. PILLING and N. RIDLEY, “Superplasticity in Crystalline Solids” (The Institute of Metals, London 1989) p. 20.

M. C. PANDEY, J. WADSWORTH and A. K. MUKHERJEE, J. Mater. Sci. 23 (1988) 3509.

A. J. SHAKESHEFF, D. S. MCDARMAID and P. J. GREGSON, Mater. Sci Technol. 7 (1991) 276.

S. C. FLOOD and J. D. HUNT, in “Metals Handbook”, 9th Edn, Vol. 15 (ASM International, Metals Park OH, 1988) pp. 130–5.

M. C. FLEMINGS, “Solidification Processing” (McGraw-Hill, New York, 1974) p. 150.

N. SONTI and M. F. AMATEAU, Numer. Heat Transf. A 16 (1989), 351.

R. D. DOHERTY, Mater. Sci. Eng. 65 (1984), 181.

D. H. KIM, B. CANTOR and H. I. LEE, J. Mater. Sci. 23 (1988) 1695.

J. H. DEVLETIAN and W. E. WOOD, Weld. Res. Council Bull. 290 (1983) 1.

D. E. J. TALBOT, “Solidification Processing 1987”, edited by J. BEECH and H. JONES (Inst. of Metals, London, 1988) pp. 29–32.

Y. ARATA, in “Proceedings of International Conference on Laser Advanced Materials Processing” (LAMP '87), Osaka, 1987, pp. 3–12.

H. TONG AND W. H. GIEDT, Weld. J. 49 (1970) 259-S.

D. A. SCHAUER and W. H. GIEDT, ibid. 57 (1978) 189-S.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Whitaker, I.R., McCartney, D.G., Calder, N. et al. Microstructural characterization of CO2 laser welds in the Al-Li based alloy 8090. JOURNAL OF MATERIALS SCIENCE 28, 5469–5478 (1993). https://doi.org/10.1007/BF00367817

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00367817