Abstract

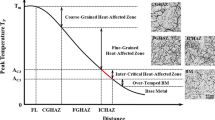

The strength-toughness-microstructure relationship in relation to the micromechanics of a fracture process has been investigated in the weld joints of two alloys: 0.5 Mo and 2.25 Cr-1 Mo steels. These alloys are extensively used to fabricate super-heater tubes, boilers, piping, gas lines, etc., by welding. The applications require high temperature and pressure to be maintained during service. The crack initiation toughness and tearing resistance were evaluated using crack tip opening displacement/J-integral parameters at different temperatures. Quantitative analysis of micro-structure and fracture surfaces was used to study the micromechanics of fracture process in the heat-affected zone (HAZ) of the alloys. Molybdenum steel exhibited a higher percentage of ferrite and lower martensite content, while the other steel showed aligned carbide as the major constituent. The higher hardness and strength values in the HAZ and welding zone (WZ) of Cr-Mo steel, compared to molybdenum steel, may be attributed to the higher amount of martensite phase in the alloy. The higher initiation toughness at 200° C in both the alloys was reflected in the larger dimple size, compared to the size observed at room temperature. A tendency for void sheet formation was noticed in both alloys. Acicular ferrite and martensite appeared to be the most influential constituents affecting tearing resistance and initiation toughness.

Similar content being viewed by others

References

R. E. RAI, P. SUNDARAM, R. K. PANDEY, A. N. KUMAR, S. K. BANERJEE and S. K. GHOSH, Eng. Fract. Mech. 37 (1990) 163.

V. R. RANGANATH, A. N. KUMAR and R. K. PANDEY, Mater. Sci. Eng. A132 (1991) 152.

P. SUNDARAM, PhD thesis, Indian Institute of Technology, Delhi (1989).

P. SUNDARAM, R. K. PANDEY and A. N. KUMAR, Mater. Sci. Eng. 91 (1987) 29.

“Annual Book of ASTM Standards”, Part 31 (American Society for Testing and Materials, Philadelphia, PA, 1973) p. 960.

British Standards Institution Document, BS5762, “Methods for COD Testing” (BSI, 1979).

“Standard Test for JIc: A Measure of Fracture Toughness”, ASME E-813-81 (ASME, 1981).

D. J. ABSON and R. E. DOLBY, “A Schematic for the Quantitative Description of Ferritic weld Metal”, Report DCC IXJ29-80 (Welding Institute, UK, 1980).

S. HOEKSTRA, Met. Construct. 18 (1986) 771.

S. K. CHAUDHARI and V. RAMASWAMY, in “Proceedings of ICF5”, France (Pergamon Press, 1981) p. 1209.

C. L. CHOI and D. L. HILL, Weld. J. 57 (1978) 232.

H. G. PISARSKI and R. J. PARGETER, in “Proceedings of the International Conference on Welding in Energy Related Projects” (1983) pp. 415–28.

C. THAULOW, Met. Const. 17 (1985) 94.

K. ERIKSSON, in “Proceedings of ICFS”, France (Pergamon Press, 1981) p. 715.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kumar, A.N., Pandey, R.K. & Sundaram, P. Microstructure-fracture toughness correlation in weld joints of Cr-Mo steel. Journal of Materials Science 30, 3531–3538 (1995). https://doi.org/10.1007/BF00349906

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00349906