Summary

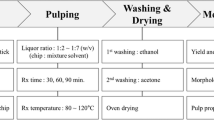

A new high-yield pulping process based on ethanol pretreatment and steam cooking was studied. The effect of processing conditions (cooking temperature at six levels and ethanol concentration at five levels) was determined. Optimum results appeared at 30% ethanol concentration and with cooking at 195 °C. The cooking liquor was analyzed by GC-MS and low-molecular lignin fragments were identified. Alcohol in alkaline medium destroys the three-dimensional lignin structure by cleavage of ether bonds, increases the penetration of the impregnation solution (higher sulfonation) and solubilizes lignin.

Ethanol treatment facilitates fiber separation in the middle lamella. Pulp prepared under optimal conditions has higher flexibility, conformability and better bonding ability when compared with other samples. Higher concentrations of ethanol (above 30%) might cause precipitation of lignin on the fiber surface.

Similar content being viewed by others

References

Alexander, L. E. 1969: X-ray diffraction methods in polymer science. In: Wiley-Interscience. p. 137. New York

Aziz, S.; Sarkanen, K. 1989: Organosolv pulping — a review. Tappi 72(5): 169–175

Barbe, M. C.; Kokta, B. V.; Lavallée, H. C.; Taylor, J. 1990: Aspen pulping: a comparison of stake explosion and conventional chemi-mechanical pulping processes. Pulp Paper Canada 12: T395-T403

Blazej, A.; Kosik, M. 1993: Phytomass: a raw material for chemistry and biotechnology. In: Ellis Horwood (Ed.). 173-221

Capretti, G.; Focher, B.; Marzetti, A.; Hua, X.; Kaliaguine, S.; Kokta, B. V. 1991: Effect of vapour-phase cooking temperature on resulting crystalline structure of sulfonated aspen fibers. Proceedings of Cellulose '91

Carrasco, F.; Kokta, B. V.; Ahmed, A.; Garceau, J. J. 1991: Ultra-high-yield pulping: relation between pulp properties and fiber characteristics by multiple linear regression. Proceedings of TAPPI Pulping Conference

Clark, J d'A. 1985: Pulp technology and treatment for Paper. In: Wet fiber compactability. Miller Freeman Publications (Ed.). 2 Ed., Chapter 21 Direction des communications du Ministère des Forêts du Québec 1990: Ressources et industries forestières — portrait statistique 1990

Fengel, D.; Wegener, G. 1984: Wood chemistry, ultrastructure, reactions. In: W. de Gruyter. New York

Girard, R. D.; Chen, R. 1992: Optimization of an organosolv process for white birch. Proceedings of Solvent Pulping Symposium 1992

Goyal, C. G.; Lora, J. H. 1991: Catalyzed organosolv pulping of North-American hardwoods: effect of pulping conditions on pulp properties and characteristics of the soluble and residual lignin. Proceedings of Pulping Conference 1991

Heitner, C.; Hattula, T. 1988: Ultra-high-yield pulping. Part VI. The effect of sulfonation on the development of Fiber Properties. J. Pulp. Paper Sci. 1: J6

Hergert, L. H.; Pye, K. E. 1992: Recent history of organosolv pulping. Proceedings of Solvent Pulping Symposium 1992

Ivanow, T.; Robert, A. 1987: Delignification par solvolyse: Role du solvant et de divers additifs. Proceedings of ISWPC 1987

Katz, R.; Beatson, P.; Scallan, A. M. 1984: The determination of strong and weak acid groups in sulphite pulps. Svensk Papperstidn. 6: R48-R53

Kokta, B. V. 1987a: Process for preparing pulp for paper making. Can. Pat. 1, 230,208

Kokta, B. V.; Vit, R. 1987b: New ultra-high-yield V-pulping process. 73rd Annual Meeting CPPA

Kokta, B. V.; Ahmed, A.; Garceau, J. J.; Chen, R. 1991: Progress of steam explosion pulping: an overview. Ellis Horwood Series in Polymer Science and Technology, 171–212

Kokta, B. V.; Ahmed, A.; Garceau, J. J.; Carrasco, F.; Deming, Z.; Huang, G. H. 1992: Steam explosion pulping (SEP) of spruce and aspen: optimization of the process. Proceeding of Papers CPPA Annual Meeting

Kordsachia, O.; Reipschlager, B.; Patt, R. 1990: ASAM pulping of birch wood and chlorine free pulp bleaching. Pap. Puu 1: 44–50

Laxen, T. 1987: The characteristics of organosolv pulping discharges. Paperi ja Puu 5: 417

Lora, J. H.; Aziz, S. 1985: Organosolv pulping: a versatile approach to wood refining. Tappi 68(8): 94–97

McDonough, T. J. 1993: The chemistry of organosolv delignification. Tappi 8: 186–193

Nimz, H. H.; Casten, R. 1985: Organosolv pulping with acetic acid. In 3rd ISWPC, Vol. 1, 256–266

Paszner, L.; Cho, H. J. 1989: Organosolv pulping: acid catalysis options and their effect on fiber quality and delignification. Tappi 72(2): 135–142

Pearl, I. A. 1967: The Chemistry of Lignin. In: M. Dekker (Ed.). New York

Sarkanen, K. V.; Ludwig, C. H. 1971 (eds.): Lignins. Wiley-Interscience, New York, 687–688

Shaw, A. C. 1984: Simulation of secondary refining. Pulp Pap. Canada 6: T152-T155

Tanahashi, M.; Goto, T.; Horii, F.; Hirai, A.; Higuchi, T. 1989: Characterization of team exploded wood III. Mokuzai Gakkashi 35: 654–662

Viswanathan, A.; Shenouda, S. G. 1971: The helical structure of cellulose I. J. Appl. Polymer Sci. 15: 519–535

Wallis, A. F. A. 1971: Solvolysis by acids and bases: In: Sarkanen, K. V.; Ludwig, C. H. (Eds.) Lignins. Wiley-Interscience, New York, p. 345

Author information

Authors and Affiliations

Additional information

The authors wish to thank the NSERC of Canada, FCAR of Quebec, Stake Tech. Co. and CQVB for their financial support. Special thanks are extended to the Stazione Sperimentale per la Cellulosa, Carta e Fibre Tessili, Vegetali ed Artificiali, Milan, Italy, for the microscopy and X-ray measurements and to the Department of Chemical Technology of Wood, Pulp and Paper, Faculty of Chemical Technology, Slovak Technical University, Bratislava, Slovakia for their expertise in GC-MS

Rights and permissions

About this article

Cite this article

Bendzala, J., Kokta, B.V. Optimization and fundamentals of high-yield pulping with ethanol. Wood Sci.Technol. 29, 467–479 (1995). https://doi.org/10.1007/BF00194205

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00194205